Posts Tagged ‘customer testimonial’

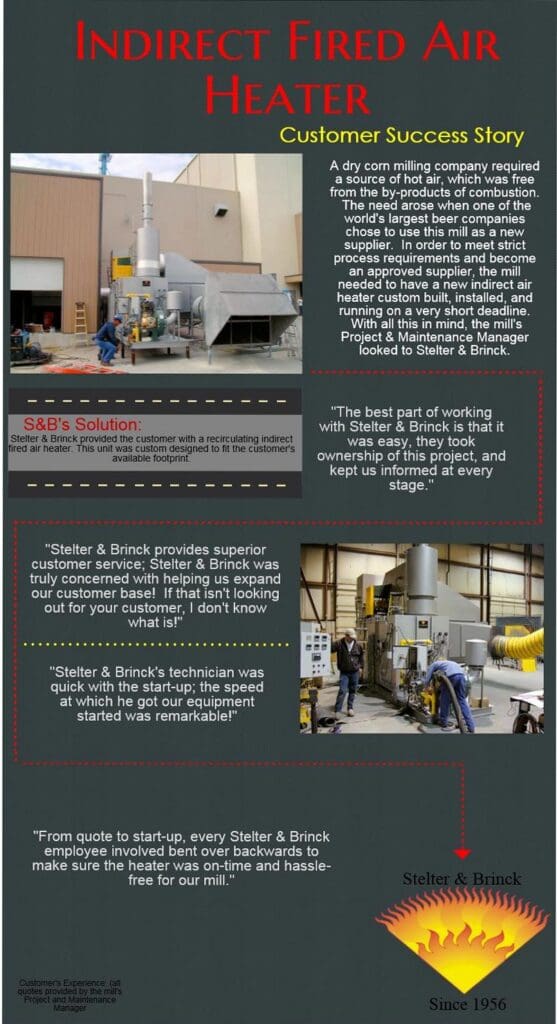

Indirect Fired Air Heater Customer Success Story

Customer Need: A source of hot air, which was free from the by-products of combustion was needed by a dry corn milling company. The need arose when one of the world’s largest beer companies chose to use this mill as a new supplier. In order to meet strict process requirements and become an approved supplier,…

Read MoreHave your Sights on 2020?

2020 is upon us and if you are in the market for any of the following process heat equipment or combustion services, Stelter & Brinck is happy to discuss your application! Process Heat Equipment Custom Designed, Engineered & Built by Stelter & Brinck: Process Air Heaters Indirect Fired Air Heaters Recirculating Non-Recirculating Straight-Through Direct Fired Air…

Read MoreThermal Oxidizer aids Rubber Products Manufacturer in Winning an Environmental Leadership Award

Situation: Due to an increase in demand in a wide area of industries- from government and consumer to wood processing and mining- the leading manufacturer of rubber products decided to expand their Nebraska plant. The plant’s new equipment helped to increased production of the company’s many products such as conveyor belts, hydraulics, hose, and rubber…

Read MoreAdhesive Coating Ovens Testimonial

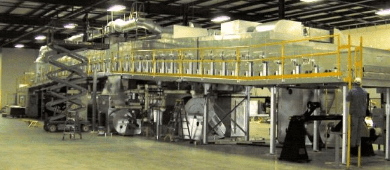

Situation: Adhesives are used in virtually every industry- from pharmaceutical and health to business and technical products. Each application is different and thus, adhesive coating equipment must have versatile and flexible manufacturing capabilities. When the coating line became dated at one of the most well-known adhesive manufacturing facilities, they knew upgrades were necessary in order…

Read More