Posts Tagged ‘thermal oxidizer’

Overview of Catalytic & Thermal Oxidizers

Harmful pollutants are generated during manufacturing, called VOCs or volatile organic compounds. To destroy VOCs before they are dispersed into the atmosphere, plants implement emission control systems. Thermal & Catalytic Oxidizers are some of the most common systems. Pollution control systems should be selected based on your application, energy efficiency and the value it will…

Read MoreThermal Oxidizer Case Study

“Our 24/7 manufacturing operation requires robust equipment. S&B has resigned our equipment to meet those standards. We are now able to keep our equipment up and running 24/7. Due to Stelter & Brinck upgrades, our equipment is very reliable.”

Read MoreCatalytic Vs Thermal Oxidizers: Characteristics and Applications

Harmful pollutants called VOCs, or volatile organic compounds, are generated and dispersed into the atmosphere during the manufacturing process of certain products. VOCs have a negative impact on the health of our ecosystem and thus throughout the years, environmental agencies have enforced emission rules for manufacturers. Oxidizers are one type of pollution control system that manufacturers…

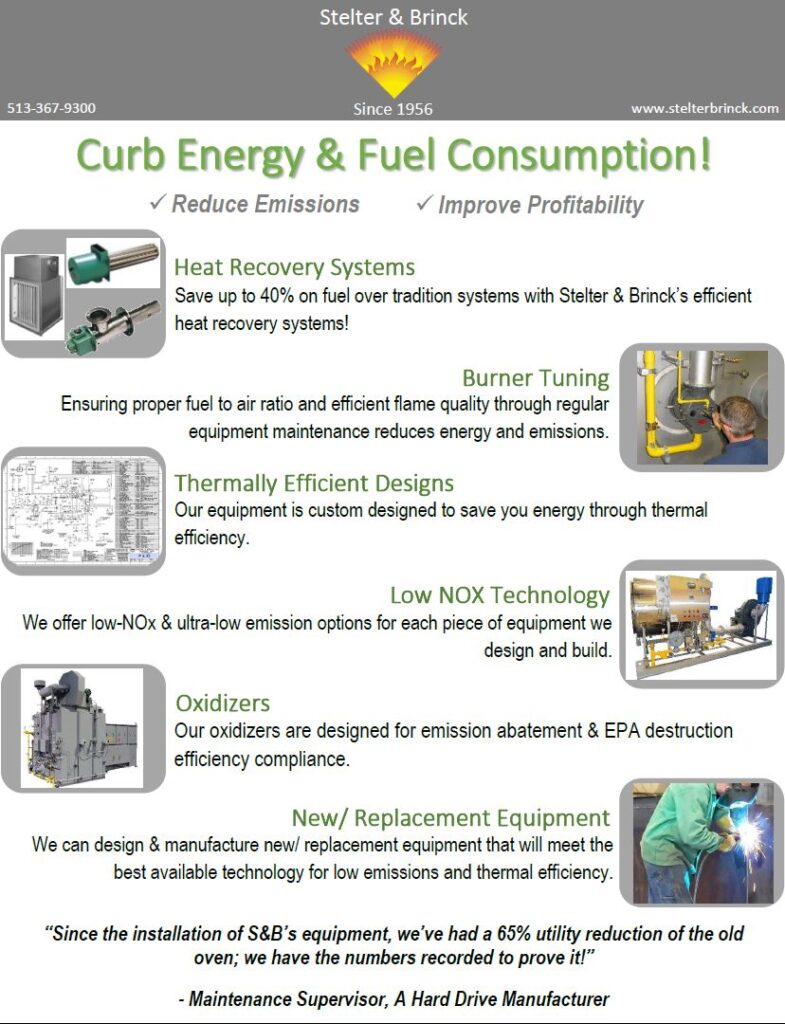

Read MoreCurb Energy & Fuel Consumption

“Since the installation of S&B’s equipment, we’ve had a 65% utility reduction of the old

oven; we have the numbers recorded to prove it!”

– Maintenance Supervisor, A Hard Drive Manufacturer

Direct Fired Thermal Oxidizer/ Afterburners

Afterburners are the simplest type of Thermal Oxidizer and are typically used in manufacturing where there are high concentrations of odor, VOCs, or smoke in the process air. Applications include: food and coffee processing, foundries, pulp & paper manufacturing, metal treatment, ect.

Read MoreThermal Oxidizers

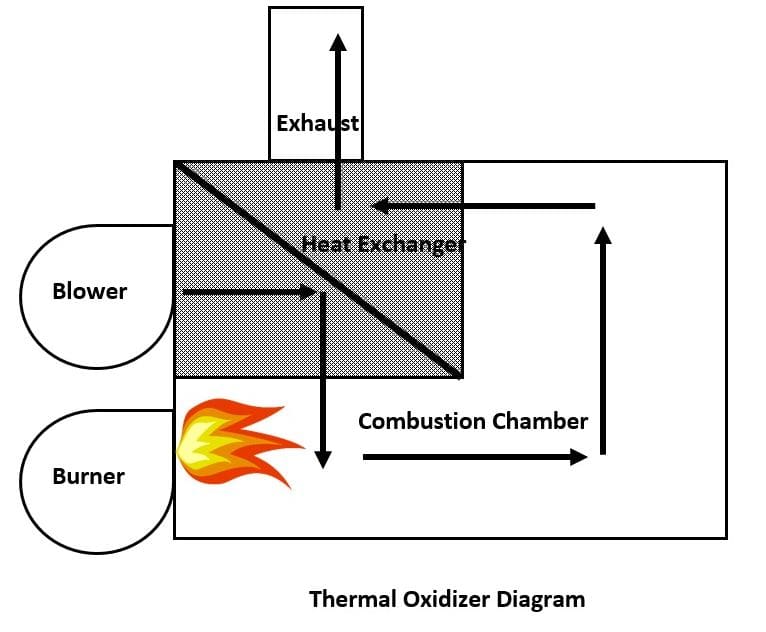

Thermal Oxidizer Overview Harmful pollutants called VOCs, or volatile organic compounds, are generated when manufacturing certain products, such as: cement, ceramics, glass, detergents, alcohol, fertilizers, pharmaceuticals, polymers, resins, and many more. Manufacturing facilities install thermal oxidizers to destroy VOCs in their process air stream before exhausting to atmosphere. The VOC latent airstream is heated to…

Read MoreThermal Oxidizer aids Rubber Products Manufacturer in Winning an Environmental Leadership Award

Situation: Due to an increase in demand in a wide area of industries- from government and consumer to wood processing and mining- the leading manufacturer of rubber products decided to expand their Nebraska plant. The plant’s new equipment helped to increased production of the company’s many products such as conveyor belts, hydraulics, hose, and rubber…

Read MoreNEW Thermal Oxidizer Video on YouTube

A couple weeks ago, we posted the basic questions we ask when a customer calls in with an industrial air pollution control system application. If you’re in the process of looking for a system to destroy the VOCs being emitted by your manufacturing process, Thermal Oxidizers are a popular method. Stelter & Brinck Thermal Fume Oxidizers can be…

Read MoreWhat to consider when purchasing an Oxidizer

Are you in the process of looking for new or replacement oxidizer? Do you need an oxidizer to destroy your industrial emissions? Are you looking to rid your industrial air stream of foul odors? In need of an afterburner for your high opacity stream? If you answered yes to any of the questions above, you…

Read MoreEmissions Goals?

Do you have emissions goals your plant strives to reach? Is your plant looking to become more environmentally friendly? Stelter & Brinck’s equipment can help you meet your emission needs! We manufacture our own line of Environmental Systems, which include: Thermal Oxidizers, Catalytic Oxidizers & Afterburners. These systems destroy industrial emissions that are present in…

Read More