Equipment Test-Firing

In-House Equipment Test-Firing

All equipment manufactured by Stelter & Brinck, Ltd. is tested and/or fired at the factory prior to shipment. The equipment is first subjected to a thorough final inspection and checklist. Where feasible each unit is set for design flow rates, temperatures, etc. All safety circuits are individually tested, and the burner is lit and fired to capacity or to utility capacity. The results of all tests are recorded along with all factory limit settings, flow rates and control settings.

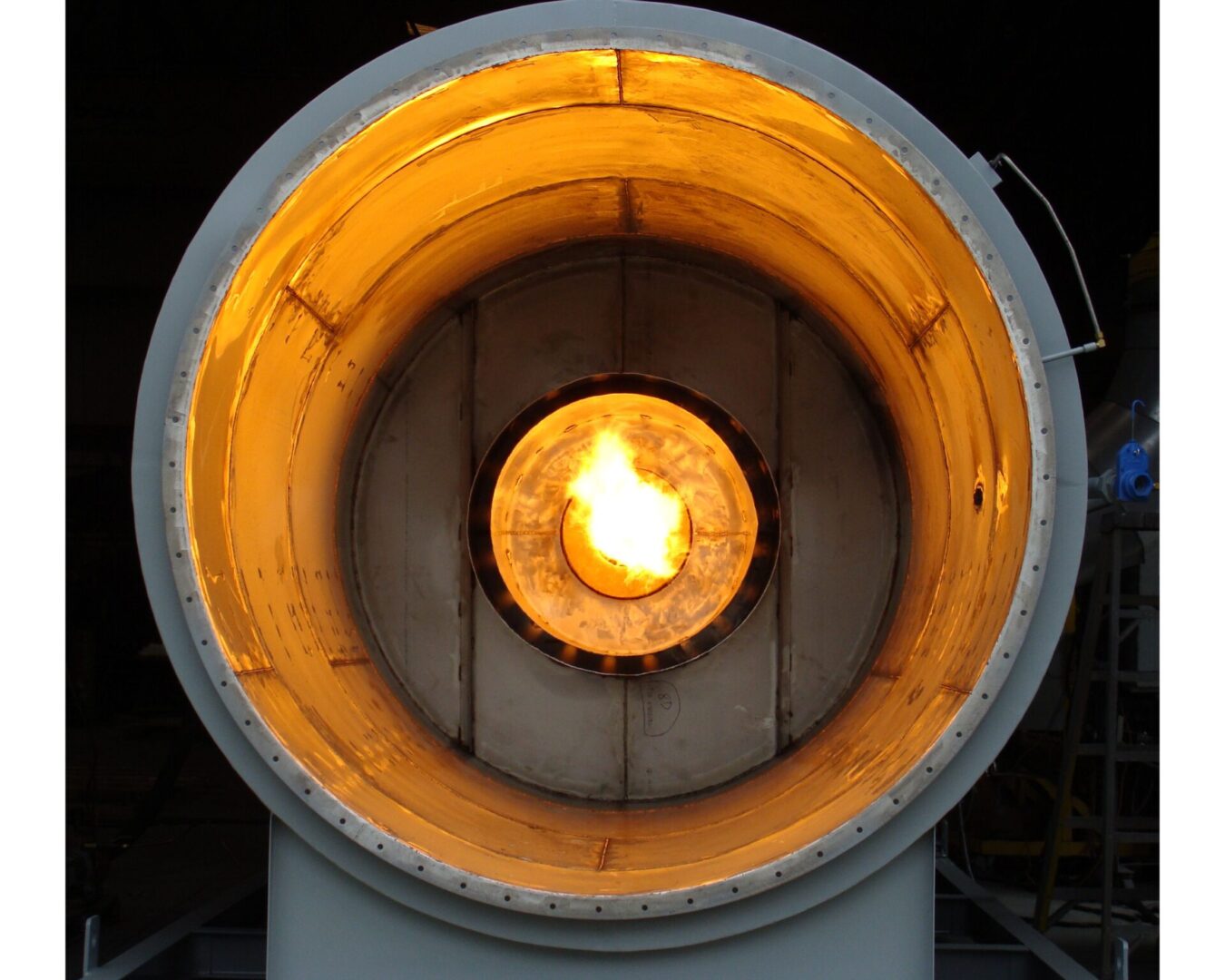

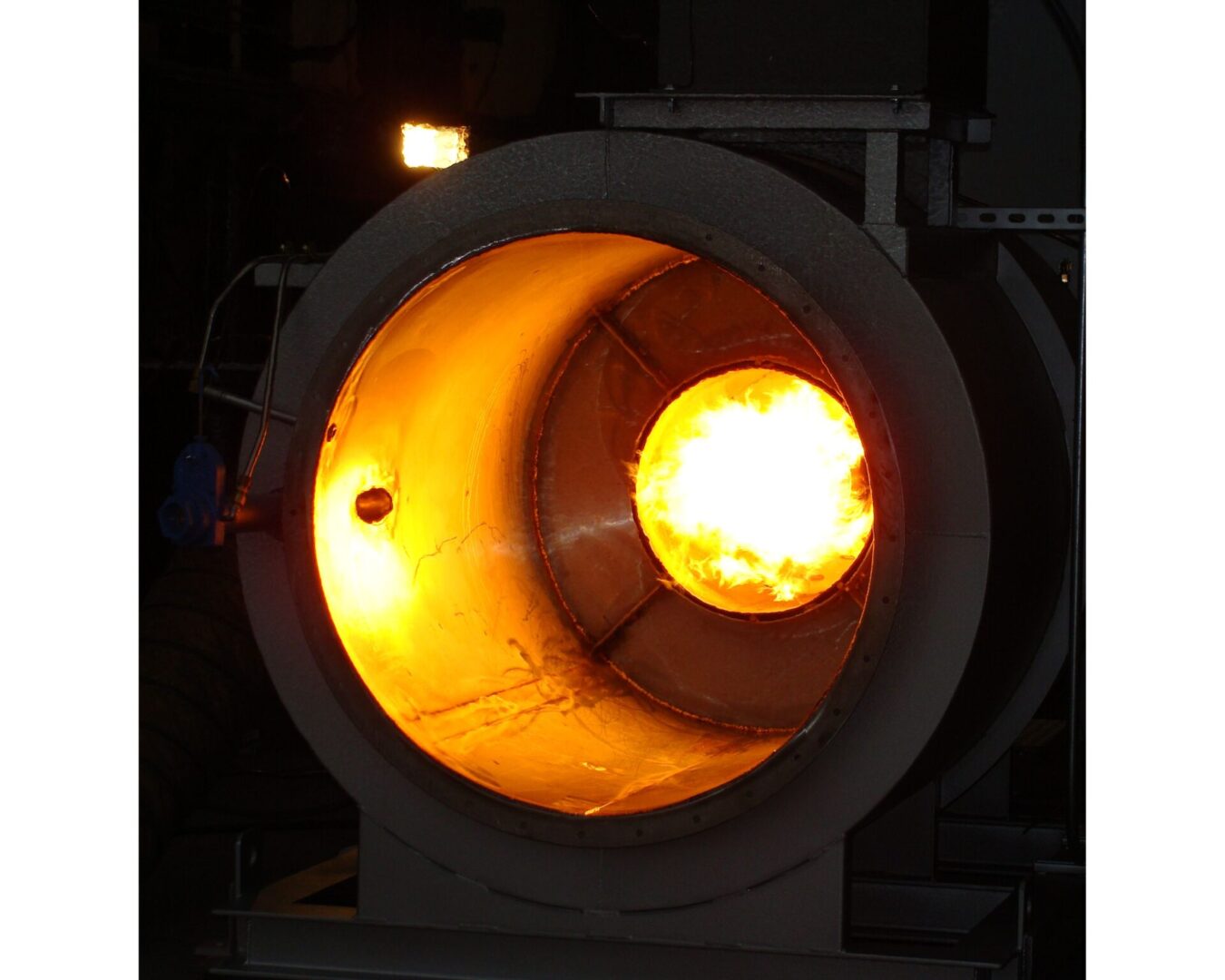

Flame from In-House Testing of Combustion Equipment

Natural Gas Combustion System Test-Firing

Process Air Heater In-House Test-Fire

Gun Style Air Heater Testing

Stelter & Brinck Equipment Testing

Car Bottom Furnace In-House Test Fire

Stelter & Brinck Test-Fire

- All equipment is rigorously tested and/or fired at the factory by our internal Quality Control Team

- Fuel oil/ Natural gas testing available

- Duplicate Overseas electric power with our in-house generator

- All safety circuits are individually tested, and the burner is lit and fired to capacity or to S&B’s utility capacity

- Reduced on-site start-up time

- Allows both OEMs and end users to adhere to tight schedules

- Results of all tests are recorded along with factory limit settings, flow rates and control settings

- The customer is always invited to our facility to witness the equipment’s firing