Speciality Ovens and Furnaces

Stelter & Brinck speciality ovens and furnaces are ideally suited for higher temperature operations or in environments that require extra heavy-duty construction not offered in traditional ovens. Among the most common applications are heat treating metals, aging aluminum, and drying and curing refractory. Our long history and vast experience in the process heat and combustion industry ensures S&B customers that the oven or furnace they purchase is not only up to construction standards, but of the highest quality and easy to use. Our flexibility of design, attention to detail, and integrity mean that every oven or furnace performs as promised.

Car Bottom Furnace

Curing Oven

Soft Metal Furnace

Car Bottom Furnace Pipe-Work

Zinc Pot- Metals Industry Furnace

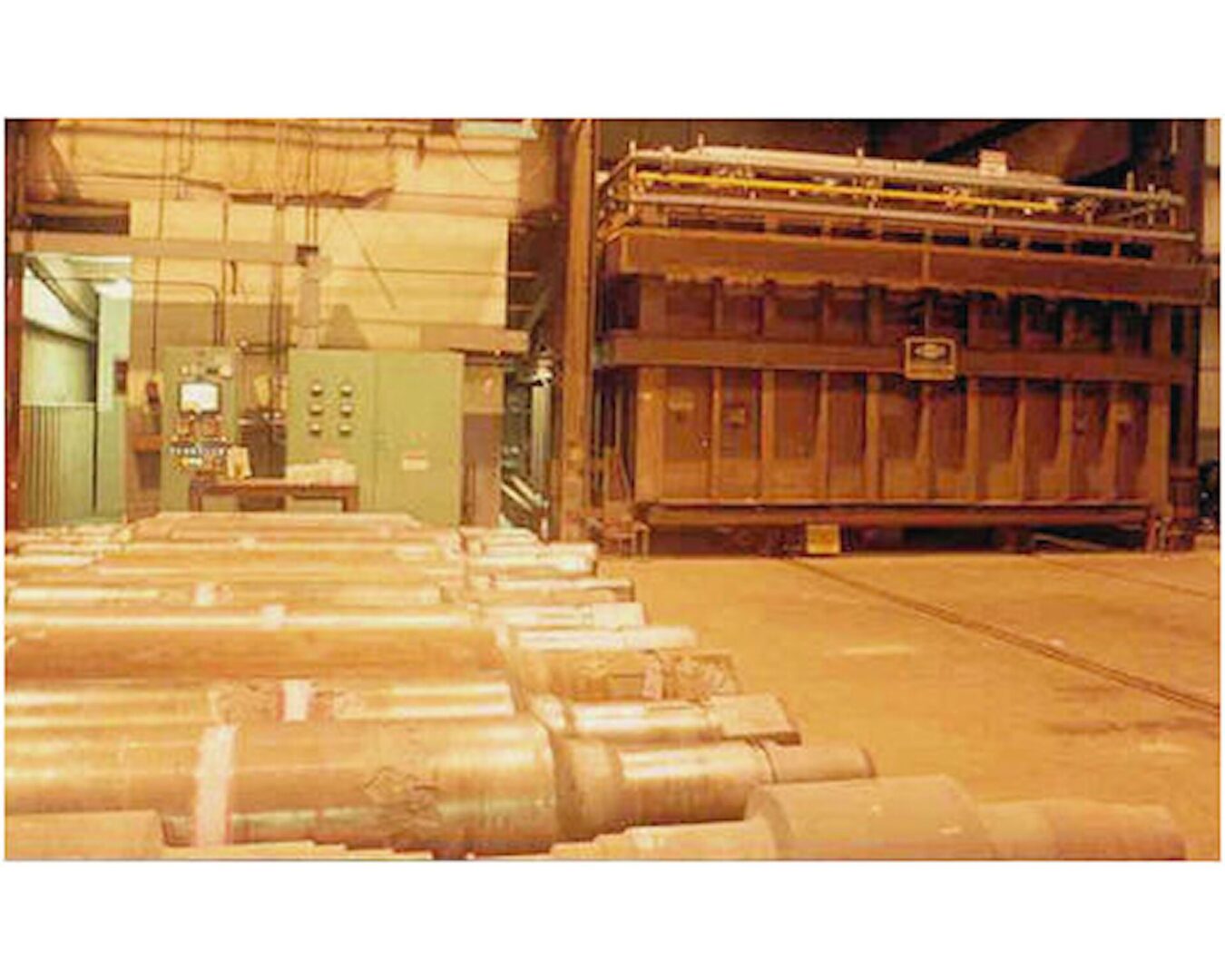

Car Bottom Furnace Installed

- Control panel with annunciator, PID digital temperature control (single or multi-loop), FM approved high temperature limit, flame safety relay, main power disconnect, control transformer, and process blower motor starter. UL 508A priced per request.

- Remote control interface capability for use with PLC or DCS systems available

- Built to meet your construction standard.

METAL MELTING/ HOLDING FURNACE

Our soft metal furnaces are designed to fit your galvanizing needs and casting workspace. Recommended for melting and/or holding lead, zinc, tin, solder, babbitt, pewter, copper, nickel and other non-ferrous metals.

BATCH STRESS RELIEVING FURNACE

Castings are loaded by fork-lift in baskets. The furnace features side to side, recirculating flow at high rates to insure uniform heating of all parts. Controls provide both ramped heat-up, soak, and cool down.

RING-STYLE HEAT TREAT FURNACE

Steel rolls for use in steel rolling mills are heat treated in these unique ring style furnaces. The furnaces can be stacked up to 16 rings high to accommodate rolls of varying lengths while leaving the roll ends outside of the furnace.

ALUMINUM SHEET COIL AGEING OVEN

Aluminium ageing oven for processing aluminium sheet in roll form. The unit included 5 heat and soak zones with extremely tight temperature uniformity. The integral conveyor handled 10 rolls simultaneously, up to 100,000 lbs. of aluminium sheet at once.

SPECIALITY TUBE FURNACE TO CURE CERAMIC COATING ON SMALL DIAMETER PIPE

A manufacturer of ceramic coated piping used in the aluminium industry required a continuous furnace to cure the coating on the pipe. This unique furnace allowed 8 parallel pipe lines to be cured. The furnace included complete controls including furnace pressure control.

PIT ANNEALING FURNACE

Pit annealing furnace with lift off lid featured high velocity combustion system and castable refractory hearth. The furnace was shipped test fired and ready for installation.