Blog

Home / Blog

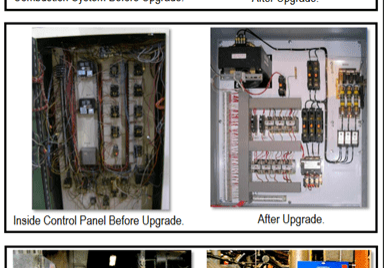

Combustion System Upgrade – Case Study

Situation: A leader in the precast shape industry decided to relocate in order to better...

(Before and After) Pictures of Combustion System Upgrades

Stelter & Brinck has been serving the process heat industry for over 100 years; today...

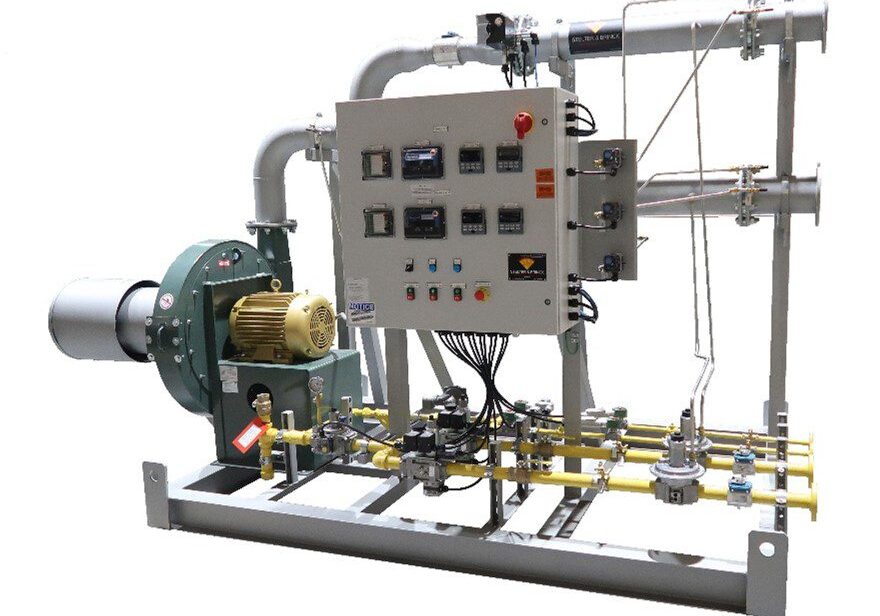

Process Combustion Systems

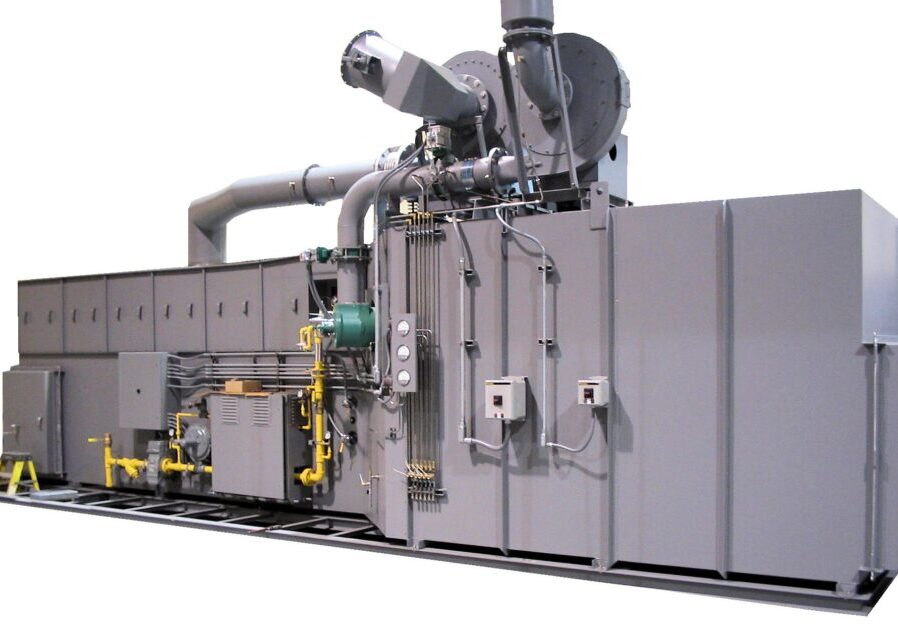

PACKAGED PROCESS SYSTEMS Burner, valve train and control panel, pre-piped and pre-wired, designed and build...

Thermal & Catalytic Oxidizer Service & Maintenance

Stelter & Brinck’s Thermal Oxidizers, Afterburners and Catalytic Fume Oxidizers are products of over 100...

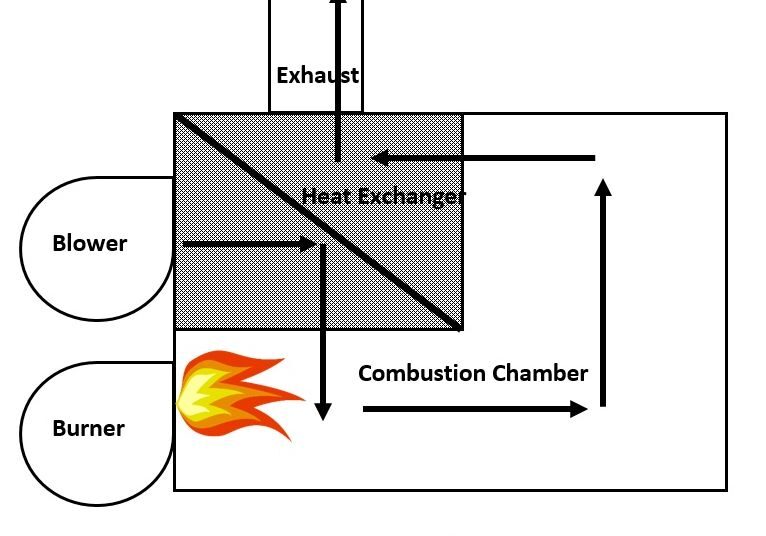

Overview of Catalytic & Thermal Oxidizers

Harmful pollutants are generated during manufacturing, called VOCs or volatile organic compounds. To destroy VOCs...

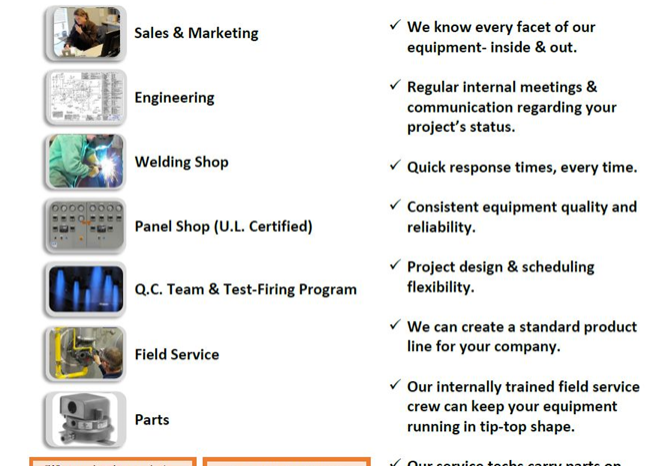

The Stelter & Brinck “In-House” Advantage

We take pride in handling every aspect of your project- from concept to departure- every...