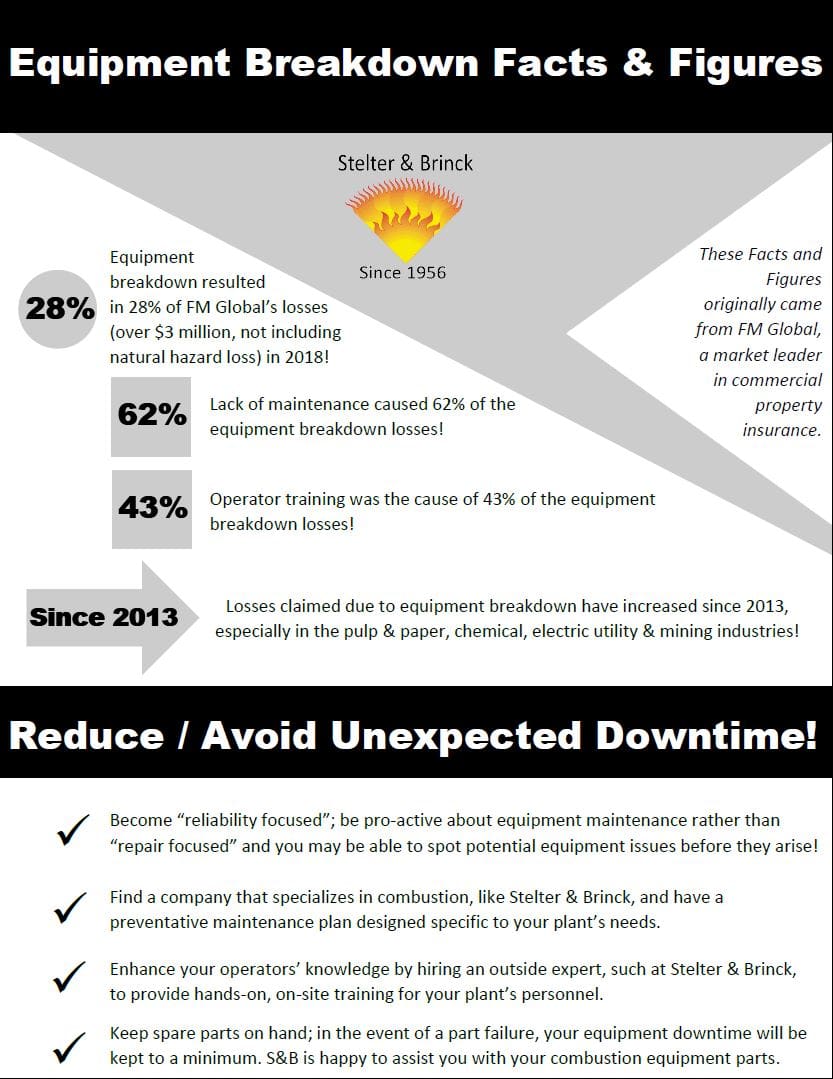

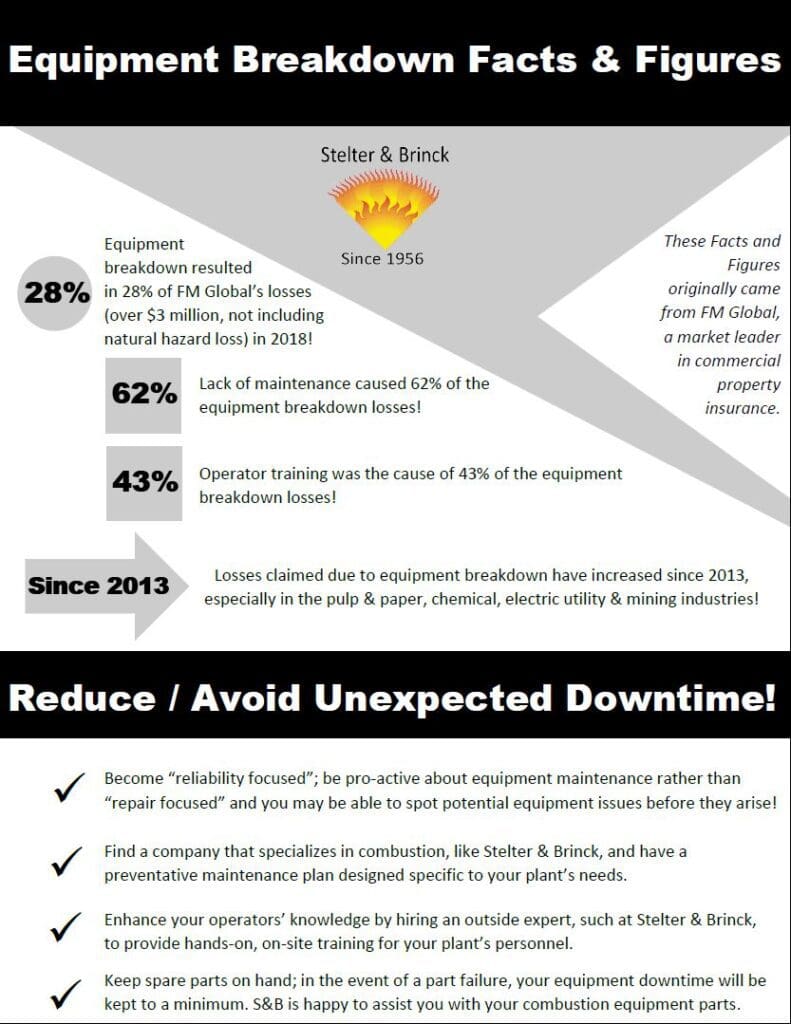

As you can see from the infographic above, according to FM Global, losses claimed due to equipment breakdown have increased since 2013, especially in the pulp & paper, chemical, electric utility & mining industries!

In order to reduce/ avoid unexpected downtime, you can do the following:

1. Become “reliability focusedâ€; be pro-active about equipment maintenance rather than “repair focused†and you may be able to spot potential equipment issues before they arise!

2. Find a company that specializes in combustion, like Stelter & Brinck, and have a preventative maintenance plan designed specific to your plant’s needs.

3. Enhance your operators’ knowledge by hiring an outside expert, such at Stelter & Brinck, to provide hands-on, on-site training for your plant’s personnel.

4. Keep spare parts on hand; in the event of a part failure, your equipment downtime will be kept to a minimum. S&B is happy to assist you with your combustion equipment parts.

For more information about Stelter & Brinck’s combustion field services, please visit our website: https://stelterbrinck.com/combustion-burner-field-services.htm