Non-Recirculating Indirect Process Air Heater (IAH-NR)

Home / Indirect Fired Air Heaters / Non- Recirculating

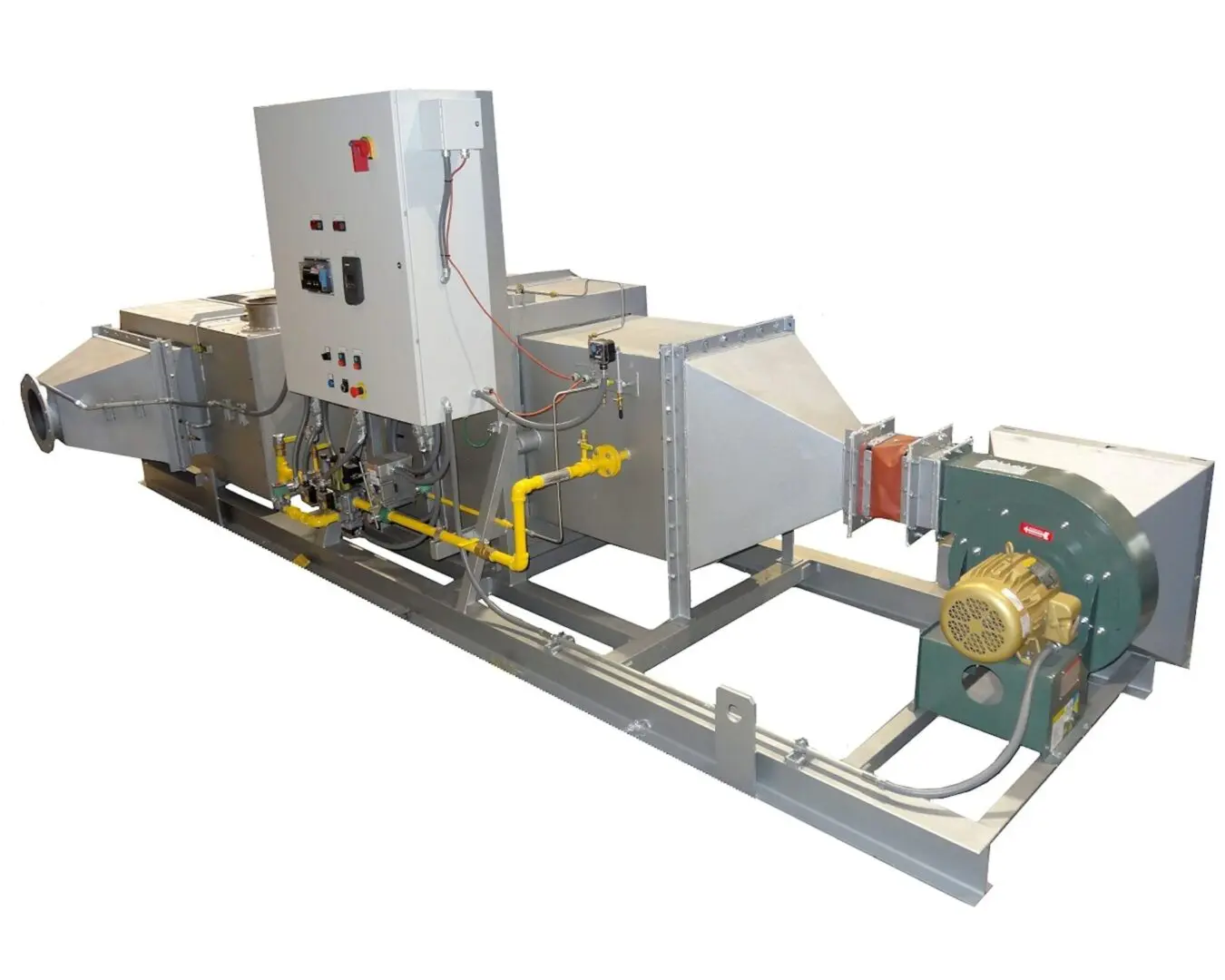

Non-Recirculating Indirect Air Heater (IAH-NR)

Typically smaller, more customizable than our IAH-R units, our non-recirculating indirect fired heaters are designed to heat your process stream, free from the by-products of combustion.

Stelter & Brinck’s non-recirculating indirect fired air heaters offer a low capital cost, medium efficiency solution to indirect heating applications. IAH-NR units are furnished complete with integral, tubular heat exchanger, burner and combustion system, and controls. These indirect process air heaters can be configured for local or remote control and can be provided in horizontal or vertical orientation, and indoor or outdoor trim to fit your plant layout requirements. Designs up to 1200°F process air outlet temperature (call factory for higher temperature requests) are standard for this indirect air heating system.

High-Temperature, Non-Recirculating, Single-Pass Indirect Air Heater

Non-Recirculating-Indirect-Fired-Air-Heater

Whether you’re drying milk or tobacco or need clean hot air for chemical manufacturing, our single-pass IAH-NRs come ready for a turn-key on-site installation:

- Structural steel skid mounted assembly available

- Prewired to control enclosure for interconnection to customer’s DCS, or remote operator station

- Integral control panel with annunciator, FM approved high temp. limits, air pressure switches, flame safety relay, main power disconnect, control transformer, PID digital temperature control, and hot side blower motor starter; UL 508A priced per request

- Built to meet your construction standard requirements

- Rigorously tested & tuned at Stelter & Brinck prior to shipment by our internal Quality Control Team

- Stelter & Brinck’s Field Service Department can keep your indirect air heater running efficiently with on-site start-up, on-going maintenance & support and access to our Parts Department

CUSTOM DESIGN OPTIONS:

- Vertical and horizontal layouts available

- Control interface for PLC or DCS operation

- Process supply blowers and ductwork

- Secondary heat recovery for producing hot air

- Stainless steel construction

STELTER & BRINCK INDIRECT AIR HEATER UNMATCHED PERFORMANCE:

Stelter & Brinck’s non-recirculating indirect fired air heaters are designed, engineered and manufactured to provide consistent and reliable performance:

- Single point fuel and power connection

- Safety fuel valve train

- High energy turn-down

- High & low process air temperatures

- PID digital process temperature control

- Can fire on natural gas or propane gas

- High turndown gas burner

- Convenient flame peep sight and pressure test taps with stainless steel I.D. tags

- Designed for ease of maintenance

- All welded heat exchanger, with heat exchanger materials chosen specifically for your application. Provides heat free from combustion by-products