About a year ago we posted a series of blogs, which highlighted four industrial dryers that utilize process air heaters. This post will discuss the processing of milk, which happens to use two of the four types of dryers: spray dryers and fluid bed dryers.

Before it can be packaged for commercial sale, all forms of milk must undergo intense processing. Milk is a very sensitive commodity- it is extremely sensitive to chemical contamination and has a short shelf life- thus, it is limited to how it is processed.

Milk powder manufacturing involves removing water from milk through evaporation, under strict hygiene conditions. The goal of is to generate a powder that has same the taste, smell/odor, nutritional and color qualities as the milk being processed. According to Wikipedia, powdered milk is “frequently used in the manufacture of infant formula, confectionery such as chocolate and caramel candy, and in recipes for baked goods where adding liquid milk would render the product too thinâ€.

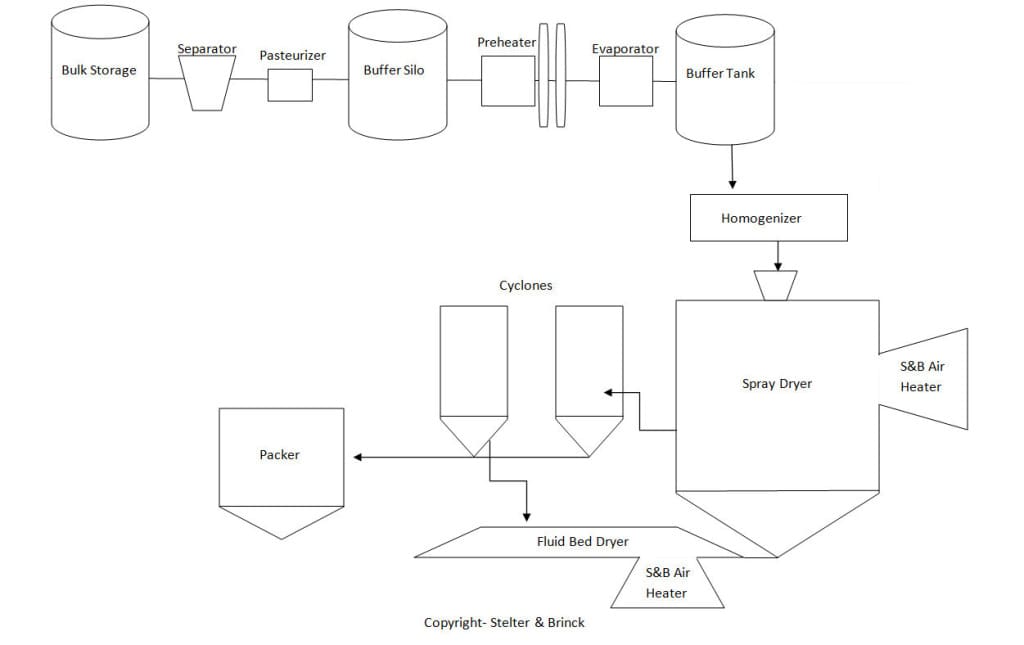

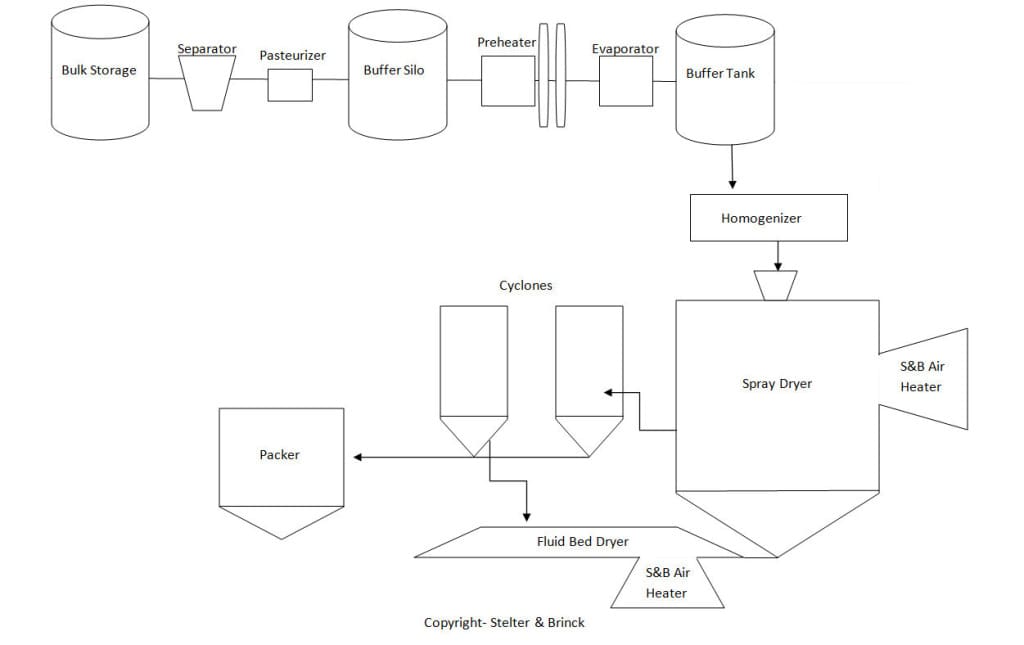

Below is a diagram of powdered milk processing.

As you can see, after the milk is collected, it is separated into cream and skimmed milk. The “creamed milk†goes onto produce cream, while the “skimmed milk†is sent to the “Pasteurizerâ€. During “Pasteurization†the milk is heated, then rapidly cooled, in order to slow the growth of bacteria. The milk is then placed through the “Evaporatorâ€- it is boiled under pressure at a low temperature, resulting in the removal of water. The milk is then placed under high pressure in the “Homogenizing Process†to improve fat solubility. Before it’s ready for packaging, the resulting milk concentrate is dried into a fine powder; first with a spray dryer, then with a fluid bed dryer.

Our spray dryer blog states that, “the air heater utilized depends upon the thermal sensitivity of the feed, an indirect fired air heater is typically used in the food, pharmaceutical and dairy industriesâ€. Because milk is a dairy product, an indirect air heater is used in conjunction with both dryers; in order to preserve the milk’s taste, smell, color, odor and nutritional values, the process air streams must be free from any products of combustion.

If you are in need of an indirect fired air heater for a spray dryer, fluid bed dryer, or any other application, feel free to contact us or fill our indirect air heater RFQ!