When purchasing a new processing system, a company typically gets bids for each individual piece of equipment, which when put together make up the entire system. The system is like a puzzle- in order for the entire process to begin running- each piece of equipment must arrive on-time and be capable of working in conjunction with the equipment provided by the other vendors. When this is the case, there can be countless problems- from scheduling to installation to commissioning. One alternative to this “multi-vendor†madness is purchasing an integrated system by a sole vendor.

Stelter & Brinck offers integrated systems; we build various custom pieces of equipment and package them together in order to form the system. Our integrated systems save our customers weeks and months of vendor selection. The total system is built to easily interconnect and because we test-fire all equipment prior to shipment, quick installation and commissioning time is possible. By taking advantage of Stelter & Brinck’s system integration, our clients are able to reduce their costs, increase their profitability and focus efforts on core business.

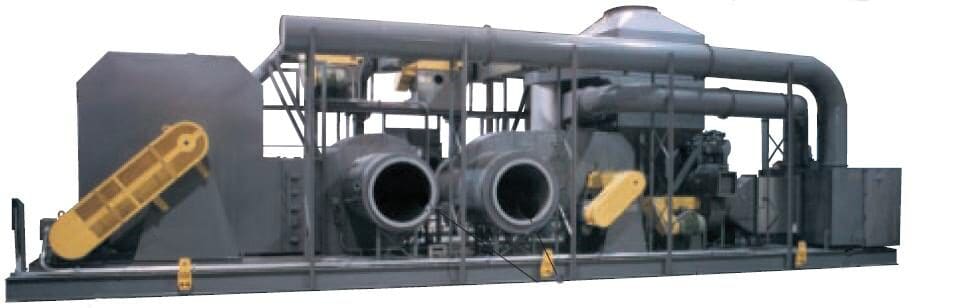

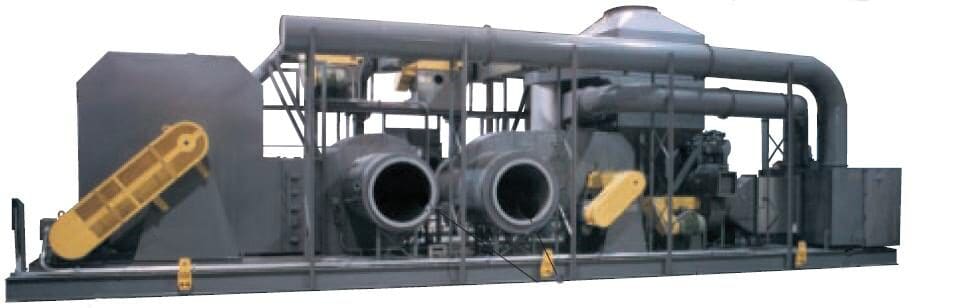

Below is a picture of a skidded integrated packaged system designed and built by Stelter & Brinck for a catalyst manufacturer.