In our last post, we discovered that cement manufacturing utilizes limestone. Therefore, we decided to focus on lime manufacturing this week! Originating with its earliest use as building mortar, lime has many end uses today: steel manufacturing, asphalt, plaster, sugar refining, wastewater treatment, and many others!

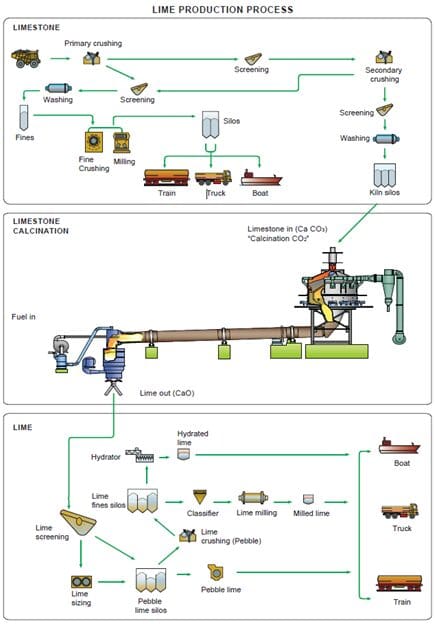

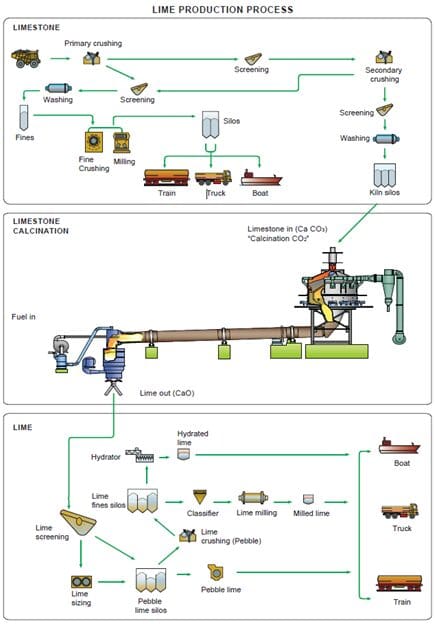

Lime Production Infographic

The National Lime Association has provided detailed lime production diagrams on their website.

The Manufacturing Process

- The limestone is mined from the quarry. The limestone undergoes crushing, which breaks it into smaller particles. The feed is screened, and the broken stones are washed.

- The clean stones are then sent through a kiln. It is at the kiln where the limestone is subjected to heat, provided by a process air heater, and “calcined†into quicklime. The air heater, typically direct fired, is placed at the lower end of the horizontally inclined kiln. The feed enters the higher end of the kiln and travels against the flow of the heated air.

According to the National Lime Association, the limestone goes through 2 stages in the kiln:

- Preheating – limestone is heated by direct contact with kiln exhaust gases.

- Calcining – the kiln fuel is burned in the preheated air from process air heater and, as the limestone moves down the kiln the heated air turns the limestone into quicklime and carbon dioxide.

3. Depending upon the end use, the quicklime is then either sold as “pebble limeâ€, further processed into “hydrated lime†by adding water, or “milled lime†by crushing and milling the quicklime.

For more information on process air heaters and how they are used in the lime industry, feel free to reach out to Stelter & Brinck.