Eggs have been a necessity, especially to the baking industry, throughout history. Not only are eggs temperature sensitive, but they are very delicate and prone to breaking. Thus transporting this dairy product is a challenge. While freezing eggs to transfer them from “place A†to “place B†was considered, powdered egg is the most ideal form.

In order to turn eggs into the powdered form, they go through the following steps:

- Sent in batches, the eggs are broken and separated from the shells.

- Pasteurization to slow microbial growth- the yolk is boiled at 149oF for a period of 6-15 minutes.

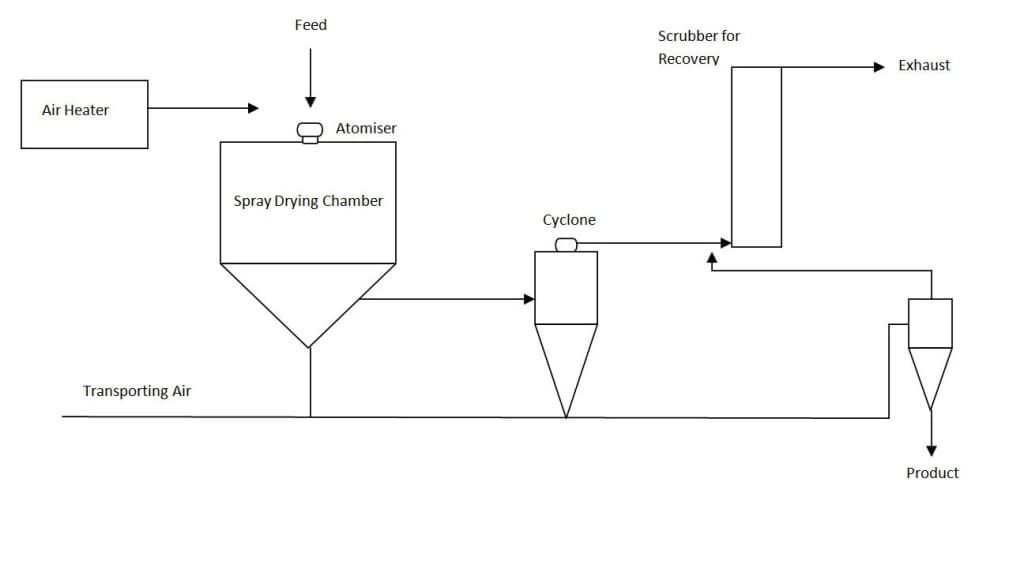

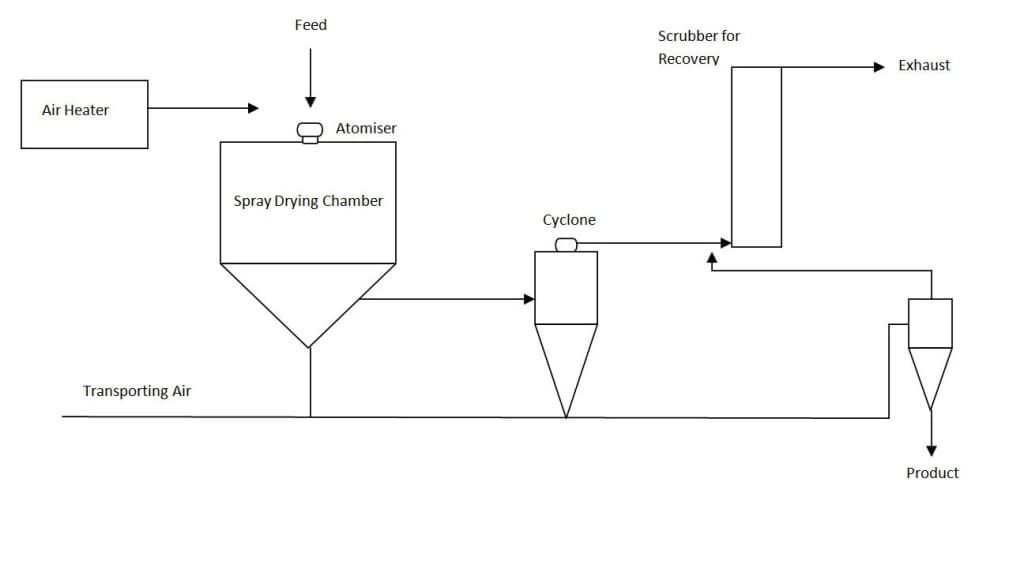

- The egg pulp is sent to a spray dryer.

Hot air is fed into the drying chamber. As mentioned on our blog discussing air heaters used in milk processing, because eggs are a diary product, “in order to preserve the [egg’s] taste, smell, color, odor and nutritional values, the process air streams must be free from any products of combustion.†Thus, an indirect fired air heater is used to produce the hot air.- Powdered egg is generated due to the combined action of the egg pulp, the dryer’s atomizer and the hot air.

Not only is powdered egg resistant to breaking, but it does not take as much space as the whole egg, is so storage and transportation of eggs is no longer an issue. In addition, powdered egg can be used with equal ease of whole eggs to bake and cook various foods.

For more information on indirect air heaters for egg powder processing or any other applications, please call 513-367-9300 or visit Stelter & Brinck at https://stelterbrinck.com/indirect-fired-air-heaters.htm