Are you in need of hot air for your industrial dryer? Indirect fired or direct fired air heaters are used as a hot air generator for many types of industrial dryers. The wet material being dried with every type of dryer determines whether the process utilizes a direct fired air heater or an indirect fired air heater; chemically sensitive products will require indirect heat.

Main Types of Dryers

The 4 main types of industrial dryers are rotary dryers, pneumatic or flash dryers, spray dryers, and fluidized bed dryers. We will discuss these dryers: we will provide a diagram, explain where an air heater is used with each, and discuss their typical product applications.

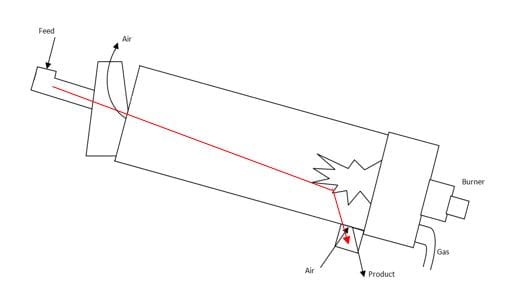

Rotary Dryers:

Diagram:

How do they work?

- The material enters the dryer.

- Material is lifted by fins on the wall’s lining as the dryer rotates.

- The material builds up on the fins.

- Material eventually falls off – gravity allows the feed to be conveyed through the dryer (red line= feed)- passing through the hot gas stream provided by the air heater.

What Industries are Rotary Dryers Used In?

Non-uniform products are best dried in a rotary drum. However, rotary drums can also dry uniform products. These dryers are mostly seen in forestry and mineral applications, such as: wood, coal, soil, fertilizers, grains, coffee beans, and many more!

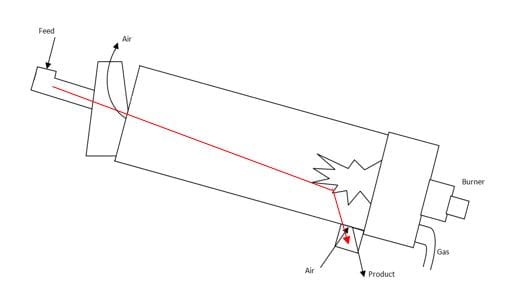

Pneumatic or Flash Dryers:

Diagram:

How do they work?

- The material is dried within seconds when it is mixed with heated air and conveyed through a duct at rapid speeds (As you can tell from the image above, the heated air is generated by a process air heater).

- After going through the drying column, the dried material is then separated using a cyclone.

What Industries Use Flash Dryers?

Used in processes where the feed is susceptible to quick drying, such as filter cakes, polymers, granules, and pastes!

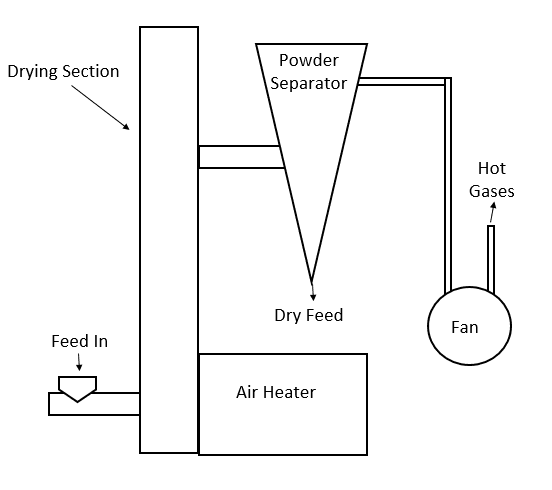

Spray Dryers

Diagram:

How do they work?

- An atomizer feeds the liquid into a drying chamber.

- When the small drops of liquid enter the chamber, they are subjected to hot air- generated by either an indirect air heater or a direct fired air heater.

- The feed turns into powder by means of water evaporation.

- The powder material is then separated using cyclones (to meet emission standards, sometimes a scrubber is used).

What Industries Use Spray Dryers?

Spray dryers are the most widely used in the food and dairy powder industries. Powdered colors, inorganic chemicals, insoluble organic dyes, and instant mixes are a few of the other products that use spray dying technology.

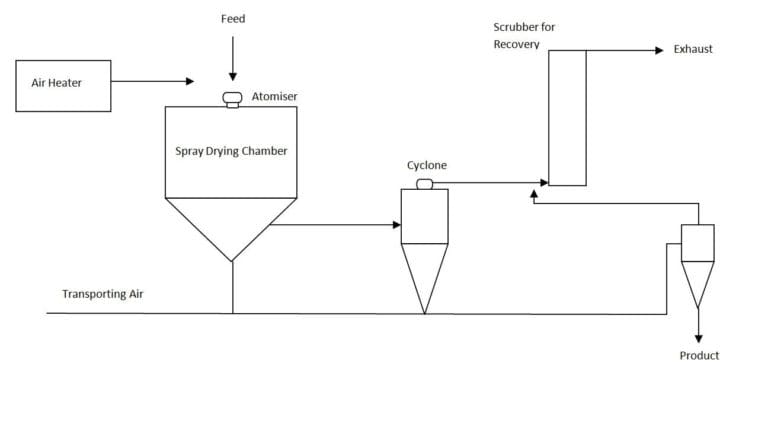

Fluid Bed Dryers

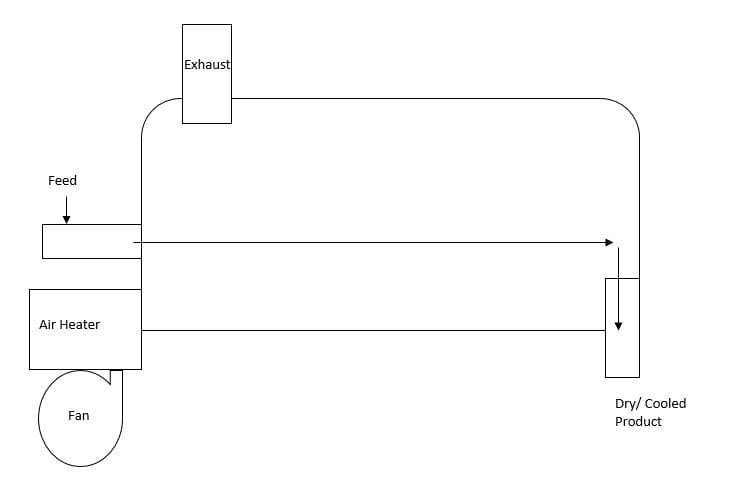

Diagram:

How do they work?

- Hot air, generated by an industrial air heater, is passed through the bed of particles.

- At the right temperature and a high enough velocity, the particles will be suspended and will begin to flow through the fluidized bed as if they are fluid.

- Dust generated from this process is sent through an outlet duct to a filter.

- The dried/cooled product is discharged at the end of the fluid bed.

What Industries Use Fluid Bed Dryers?

These dryers are used for bulk materials that do not vary much in size. A few of the products that are dried with fluid beds include: clay, pigments, powders, cement, biomass, minerals and more!

If you have questions about Stelter & Brinck’s direct or indirect fired air heaters for use with industrial dryers, or for any other application, feel free to contact us!