As we mentioned last week, there are 4 main dryer systems that use process airs: rotary dryers, pneumatic/flash dryers, spray dryers, and fluidized bed dryers.

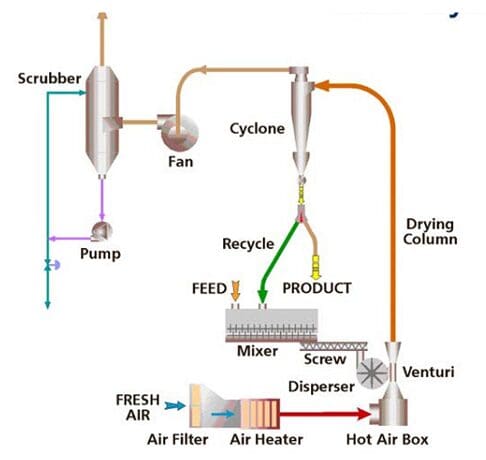

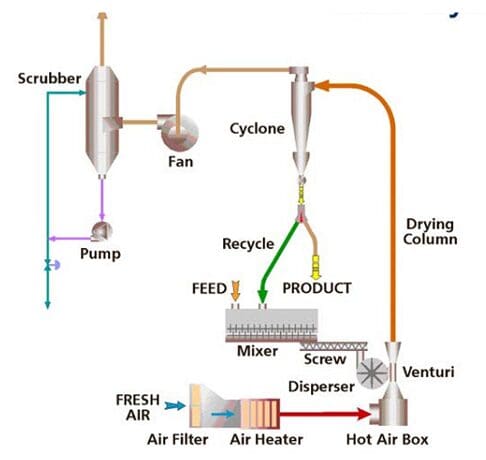

This week we will focus on pneumatic/flash dryers (we will refer to them as flash dryers). Flash dryers make up some of the largest dryers in the world! These dryers are used in processes where the feed is susceptible to quick drying; filter cakes, polymers, granules, pastes, ect. Below is a diagram of a flash drying system:

Diagram of a Flash Dryer

Image from “Best Practice Manual-Dryersâ€- http://www.energymanagertraining.com/bee_draft_codes/best_practices_manual-DRYERS.pdf

The wet material is mixed with heated air and conveyed through a duct at rapid speeds. After going through the drying column, the dried material is then separated using cyclones. A scrubber is also sometimes used with flash dryers in order to meet emission standards. The entire process, from wet feed through cyclone takes just seconds!

As you can tell from the image above, the heated air is generated by a process air heater; typically, direct fired air heaters are used with flash dryers, as the material tends to not be chemically sensitive.

If you need a hot air source for your flash dryer, Stelter & Brinck can custom design and manufacture an air heater to fit your application and physical space. Our air heaters provide unmatched quality and are designed to be easy to use, install and maintain. Built to meet your construction standards, the air heater will be subjected to S&B’s exclusive QC and test-firing program before shipment. Start-up and regular maintenance of your air heater are available, as always, through S&B’s field service department.