Afterburners

Afterburners are the simplest type of Thermal Oxidizer. These environmental systems are also called Direct Fired Thermal Oxidizers, Enclosed Flares or Vapor Combustors and are used to destroy industrial pollutants.

Afterburners are recommended for use when there is a very high concentration of VOCs in the process air. Applications include: food and coffee processing, foundries, pulp & paper manufacturing, metal treatment, ect.

During the thermal combustion process, the pollutants are chemically changed into harmless combustion by-products, water and carbon dioxide, both of which can be discharged through the exhaust.

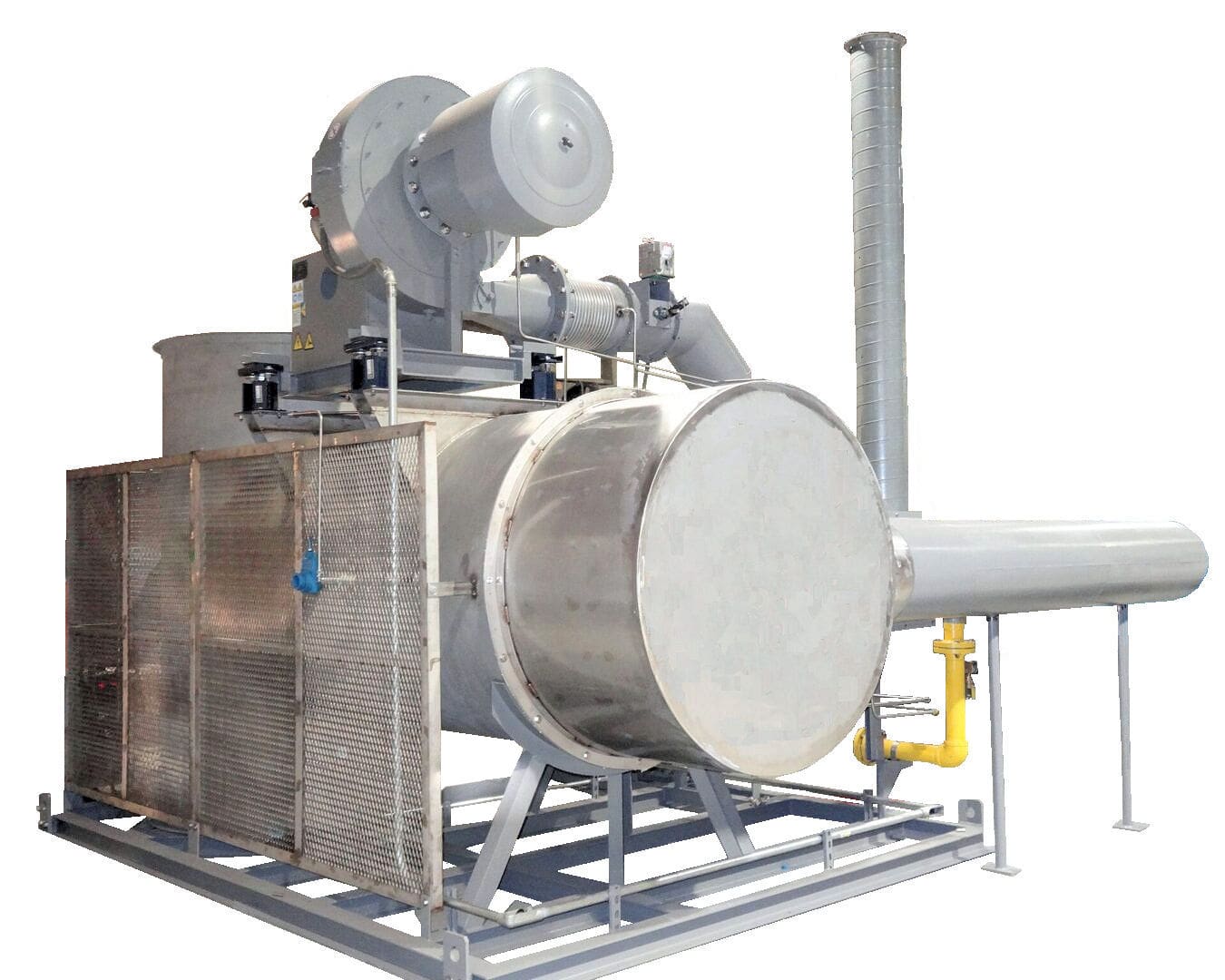

Afterburner - Enclosed Flare - Vapor Combustor

Afterburner - Direct Fired Thermal Oxidizer

Thermal Afterburner Stack Being Loaded in S&B's Shop

Direct Fired Thermal Oxidizer- Afterburner for Industrial Pollution

Thermal Afterburner

FEATURES

S&B direct fired thermal oxidizers (afterburners) are designed to be easy to use and install, among the features offered are:

- Skid mounted packaged units are prepiped, prewired

- PID digital temperature control, FM approved high temp limit, flame safety relay, main power disconnect, and control transformer; UL 508A priced per request

- AWS D1.1, D1.3, D1.6 certified welders

- Remote control interface capability for use with PLC or DCS systems available

- Built to meet your requirement (FM, CE, GAP, NFPA or CSA construction standard)

- In-House test firing and tuning prior to shipment reduces start-up and installation costs

- On-going Afterburner maintenance available

ADVANTAGES OF OUR DIRECT-FIRED AFTERBURNERS:

Stelter & Brinck thermal afterburners are a product of more than 95 years of industrial combustion experience.

- 99+% destruction removal efficiency (DRE) available

- Castable refractory

- High temperature aluminium paint

- Vertical orientation saves valuable floor space

- Single point utility connections for ease of installation

- Nozzle mixing burner with dedicated combustion air blower

- Venturi design, no process fan necessary

- Halogen compatible designs available

- Custom designed air pollution control systems are available per application