Aluminum Sow Dryers

Aluminum Sow Dryers

Stelter & Brinck aluminum sow dryers/ preheaters are available in two versions: a lift-off portable unit that can be moved to new locations with ease and a dual station, fixed location model. Both models are custom designed to fit your sow geometry and load requirements. Sow dryers provide a dry charge and the production advantages of a preheated hot charge to your melter.

Installed Sow Dryer at Customer's Plant

Control Panel for Sow Dryer/ Preheater

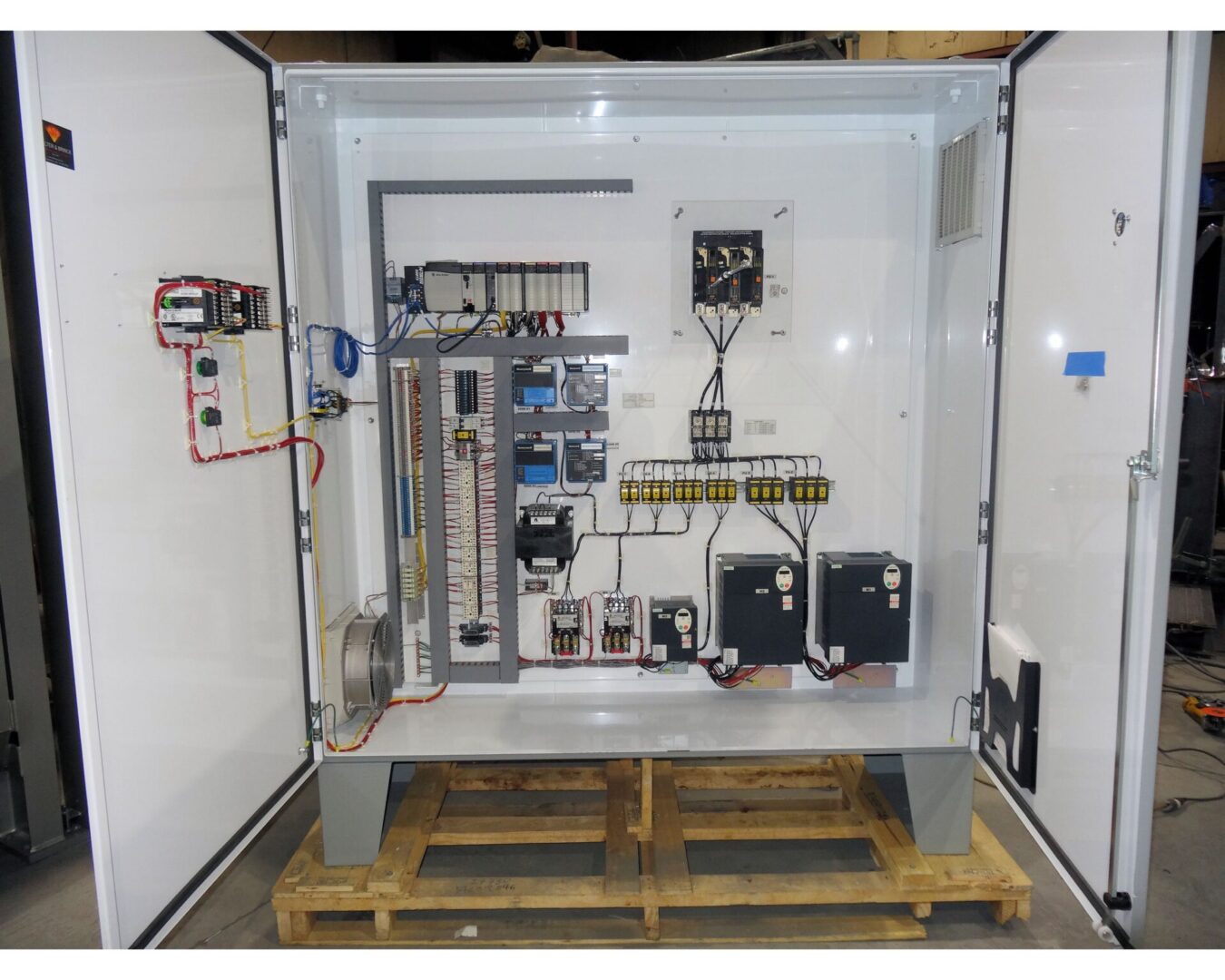

Inside Sow Equipment Control Panel

Sow Dryer & Control Panel

Sow Dryer loaded - heading to customer's facility.

Aluminum sow dryers are designed to be easy to use and install, among the features offered are:

- Control panel with annunciator, PID digital temperature control, FM approved high temperature limit, flame safety relay, main power disconnect, control transformer, and blower motor starter or VDF. UL 508A priced per request.

- Remote control interface capability for use with PLC or DCS systems available.

- Built to meet your requirements (FM, CE, GAP, NFPA or CSA construction standard).

- Test-fired & tuned in our shop prior to shipment. We can also provide on-site start-up and regular preventative maintenance visits.

- Single-piece construction – just place over sows and fire!

S&B’S SUPERIOR EQUIPMENT:

Stelter & Brinck dryers are designed to provide unmatched performance. Our dryers are a product of more than 95 years of industrial combustion experience and feature:

- Precise temperature control.

- Easy maintenance, easy access to all parts.

- Uniform drying and preheating of sows.

- Portable design facilitates flexible plant layouts.