Straight-Through Indirect Air Heater (IAH-ST)

This unit is small and mighty – our most compact indirect air heating model, our straight-through indirect fired air heater (IAH-ST) does not lack in efficiency, reliability or performance.

Whether you’re drying hydrated lime, spray drying dairy products, or drying chemicals and pharmaceuticals, S&B’s IAH-ST heaters are ideal for applications that require hot, clean air. With heat exchangers that can be mounted on the positive or negative side of the process, the straight-through heater will maximize space in your layout. Our IAH-ST is custom designed to meet your project’s requirements and to be industrial, reliable and “plug and play”.

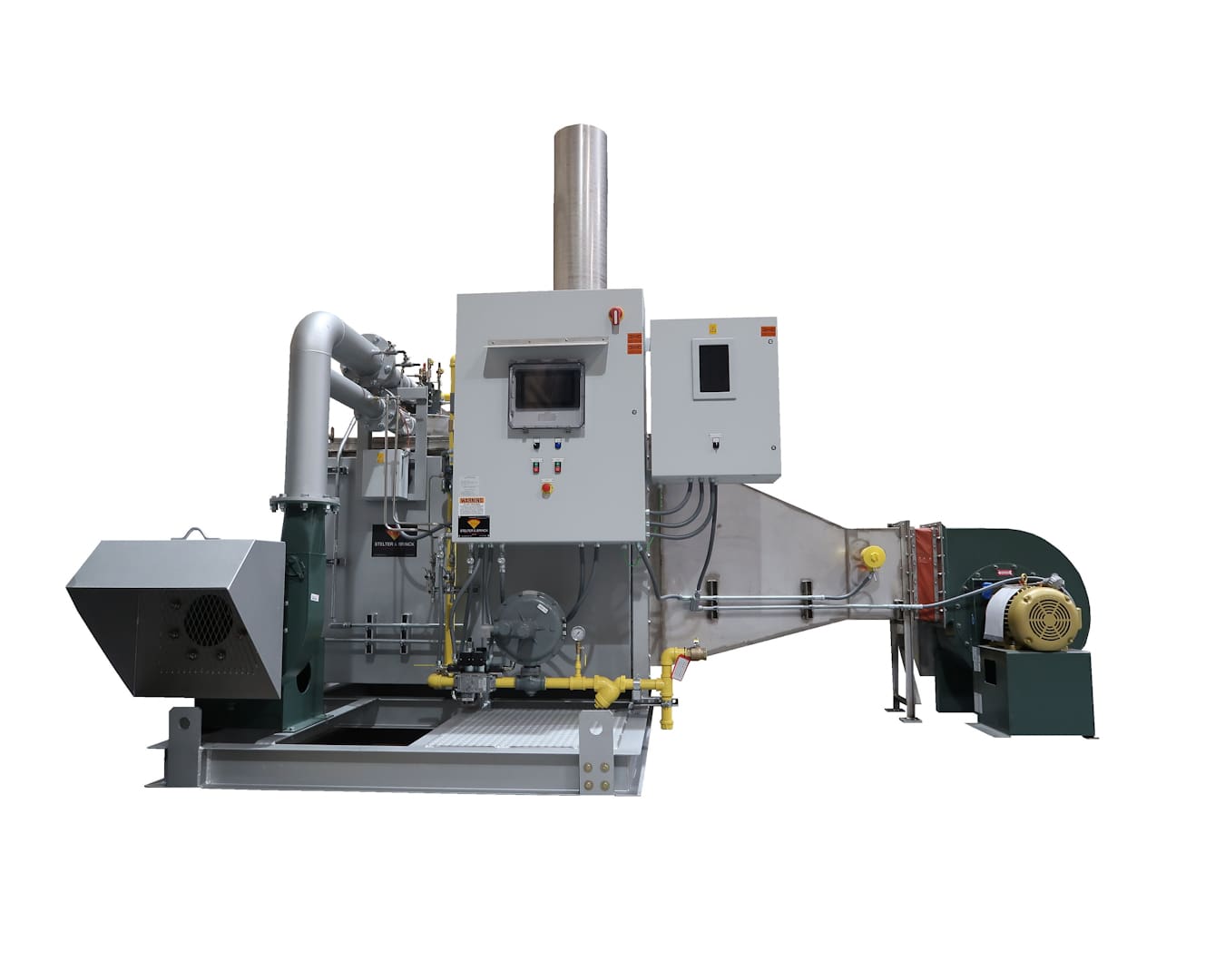

Indirect Air Heater with Process Air Blower & Slate Controls

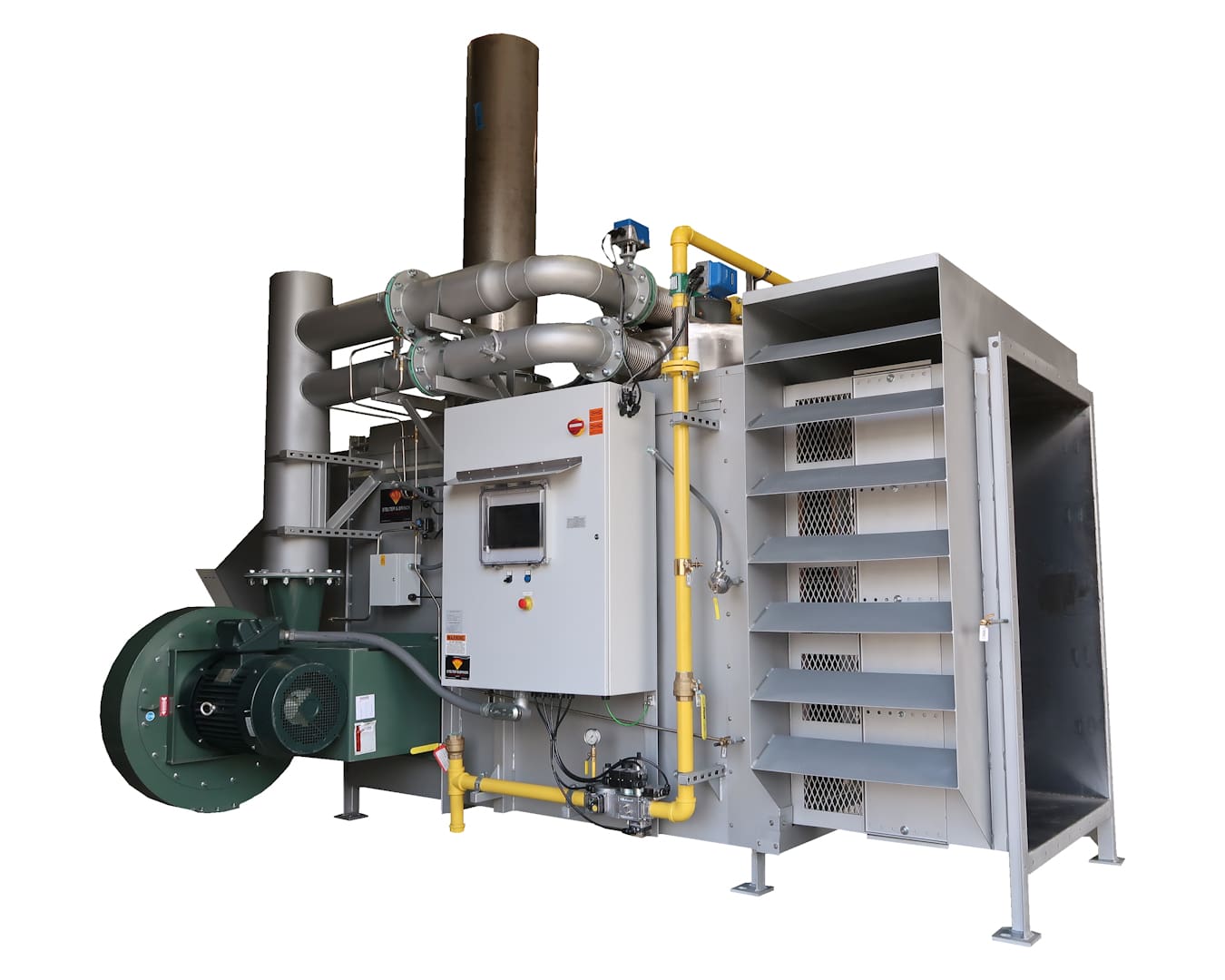

Indirect, Straight-Through, Air Heater with Process Air Transitions

Compact, Straight-Through Air Heater

Straight-Through Indirectly Fired Process Air Heater for Industrial Applications

Highly efficient, Straight Through Indirect Heater with Process Air Transitions

Stainless Indirect Fired, Straight-Through, Air Heater

Vertical, Straight-Through, Indirect Heater

FEATURES

S&B’s IAH-ST units are designed, engineered and manufactured to provide consistent and reliable performance. These process air heaters are easy to use and install, among the features offered are:

- Fully welded, all stainless heat exchangers

- Process contact surfaces built of high-grade stainless: 304, 316 & 321 available

- Prewired to control enclosure for interconnection to customer’s DCS, or remote operator station

- Integral control panel with annunciator, FM approved high temperature limits, air pressure switches, PID digital temperature control, flame safety relay, main power disconnect, control transformer, and hot side blower motor starters; UL 508A priced per request

- Built to meet your construction standard requirements

- AWS D1.1, D1.3, D1.6 certified welders

- Insulated and skinned combustion chamber

- Rigorously tested and tuned, in-house, prior to shipment

- On-site start-up and on-going maintenance available world-wide through S&B’s Field Service Department

CUSTOM DESIGN OPTIONS:

- Recirculating or non-recirculation configuration

- Horizontal or vertical available

- Low emissions option available

- Control interface for PLC or DCS operation

- Process supply blowers transitions

- Secondary heat recovery for producing hot air

ADVANTAGES OF A STELTER & BRINCK STRAIGHT-THROUGH INDIRECTLY FIRED AIR HEATER:

A product of more than 95 years of experience with process heat equipment, Stelter & Brinck straight-through indirect air heater units provide unmatched performance, in a compact design. Advantages:

- Single point connections for fuel and power

- Thermal efficiencies to 90%

- High energy turn-down

- High & low process air temperatures

- PID digital process temperature control

- Indirect air heaters can be provided to fire on natural gas and propane gas

- Flame peep sight, pressure test taps and stainless steel I.D.’s throughout

- Designed for easy cleaning and maintenance

- All welded stainless steel heat exchanger

- Robust, reliable system provides heat without free from combustion by-products