Aluminum Sow Dryers

Stelter & Brinck aluminum sow dryers/ preheaters are available in two versions: a lift-off portable unit that can be moved to new locations with ease and a dual station, fixed location model. Both models are custom designed to fit your sow geometry and load requirements. Sow dryers provide a dry charge and the production advantages of a preheated hot charge to your melter.

Installed Sow Dryer at Customer's Plant

Control Panel for Sow Dryer/ Preheater

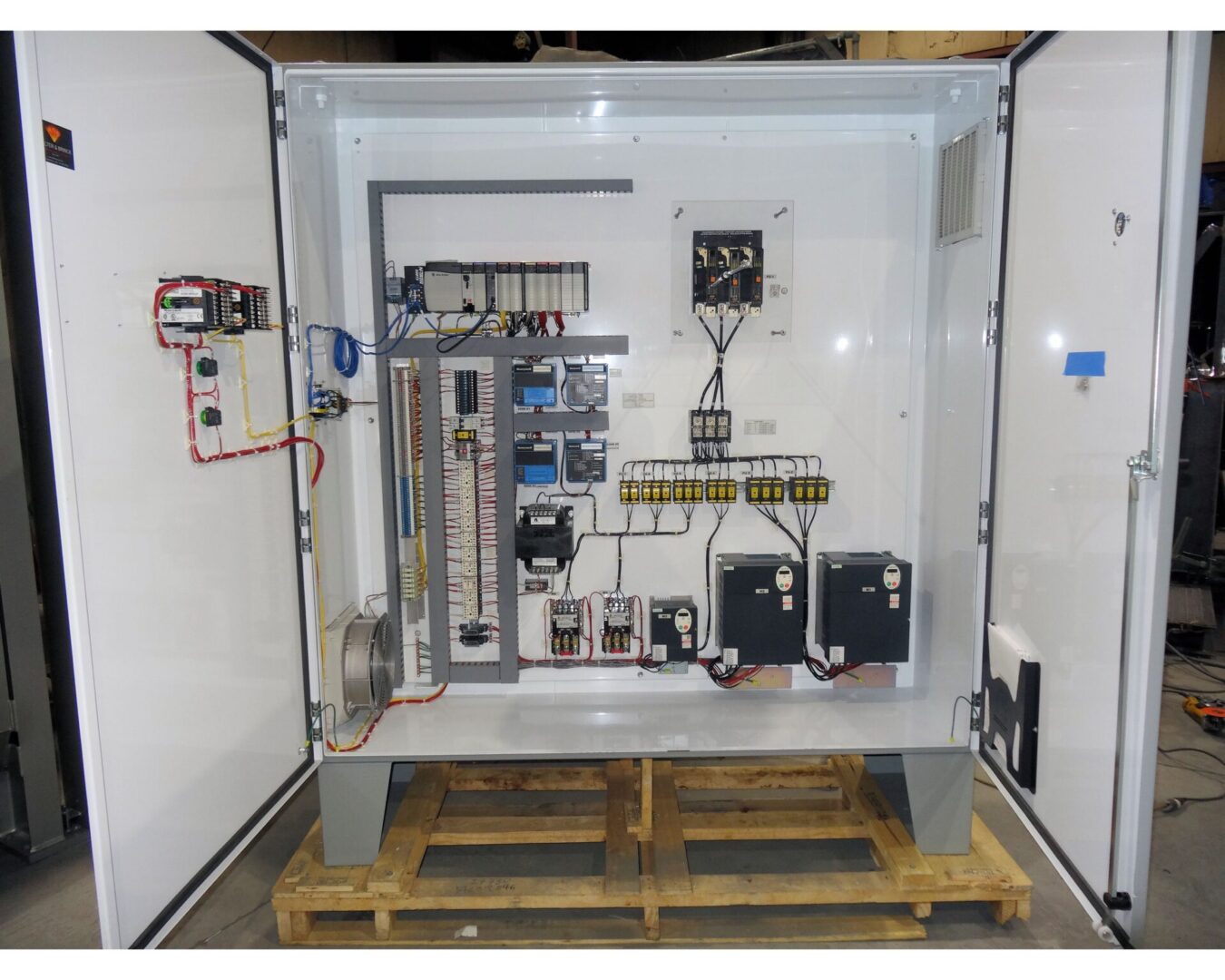

Inside Sow Equipment Control Panel

Sow Dryer & Control Panel

Sow Dryer loaded - heading to customer's facility.

FEATURES

Stelter & Brinck tundish dryers/ dryer-preheaters/ preheaters are completely packaged with burners and controls. These units offer the utmost in customer convenience coming as prewired and prepiped assemblies.

Stelter & Brinck tundish dryers/dryer-preheaters/preheaters are designed to be easy to use and install, among the features offered are:

- Control panel with annunciator, PID digital temperature control, FM approved high temperature limit, flame safety relay, main power disconnect, control transformer, and combustion blower motor starter; UL 508A priced per request

- Remote control interface capability for use with PLC or DCS systems available

- Built to meet your construction standard (FM, CE, GAP, NFPA or CSA)

- AWS D1.1, D1.3, D1.6 certified welders

- On-site start-up and on-going combustion equipment maintenance available

BENEFITS OF S&B’S MILL EQUIPMENT:

Stelter & Brinck dryers are designed to provide unmatched performance. Our dryers are a product of more than 95 years of industrial combustion experience and feature:

- Precise temperature control for accurate ramp and soak programs.

- Multiple burner systems assure uniform results.

- Standard units fire on natural gas. Other fuel options available on request.

- Lift-off and tilt-style units available.