Posts Tagged ‘Scheduled burner maintenance’

Importance of Burner Maintenance in Today’s Workplace

Today, people are “doing less with more” in the workplace. Companies are finding more effective ways to allocate resources. The main reason people are able to yield higher output is due to advancements in technology. Technology has given people the ability to have resources and information at their fingertips, anytime and anyplace. In turn, our…

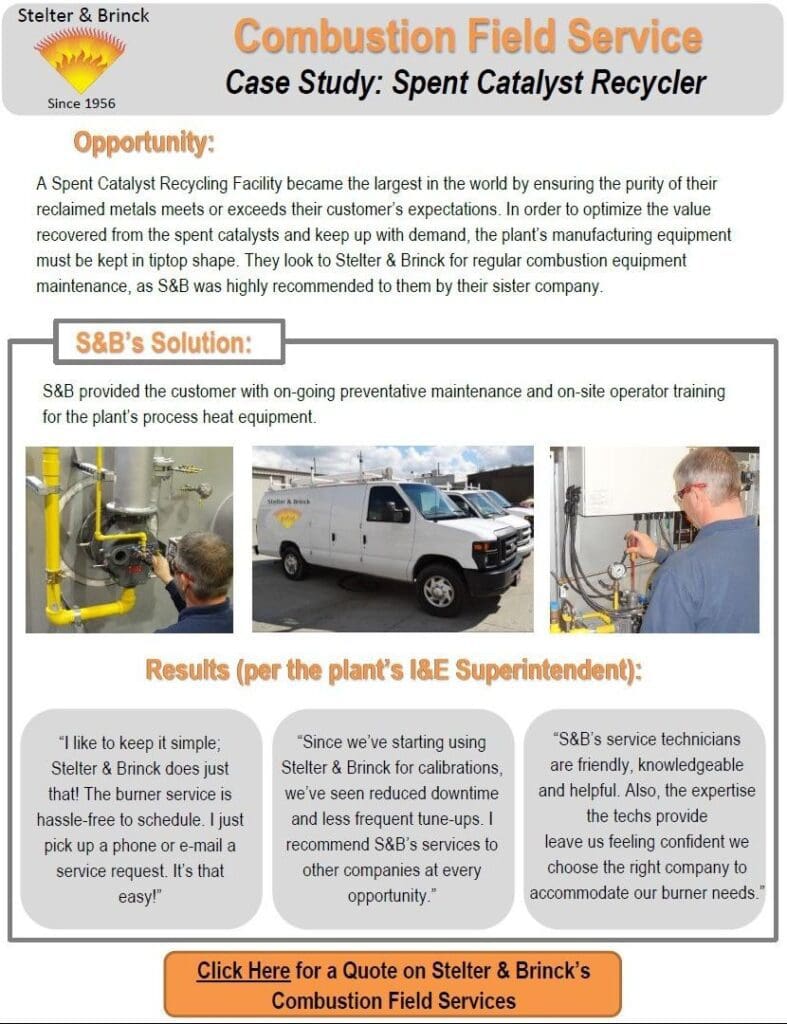

Read MoreScheduled Burner Preventative Maintenance Case Study: Wood Plastic Composite Manufacturer

Situation: Composite wood is manufactured by combining particles of wood together with plastic. Since its introduction into the outdoor living market in the 1990’s, composite has become a popular alternative to traditional wood decking and railing. Not only is composite easy to install and maintenance-free, but it doesn’t rot, warp, fade, weather or splinter. In…

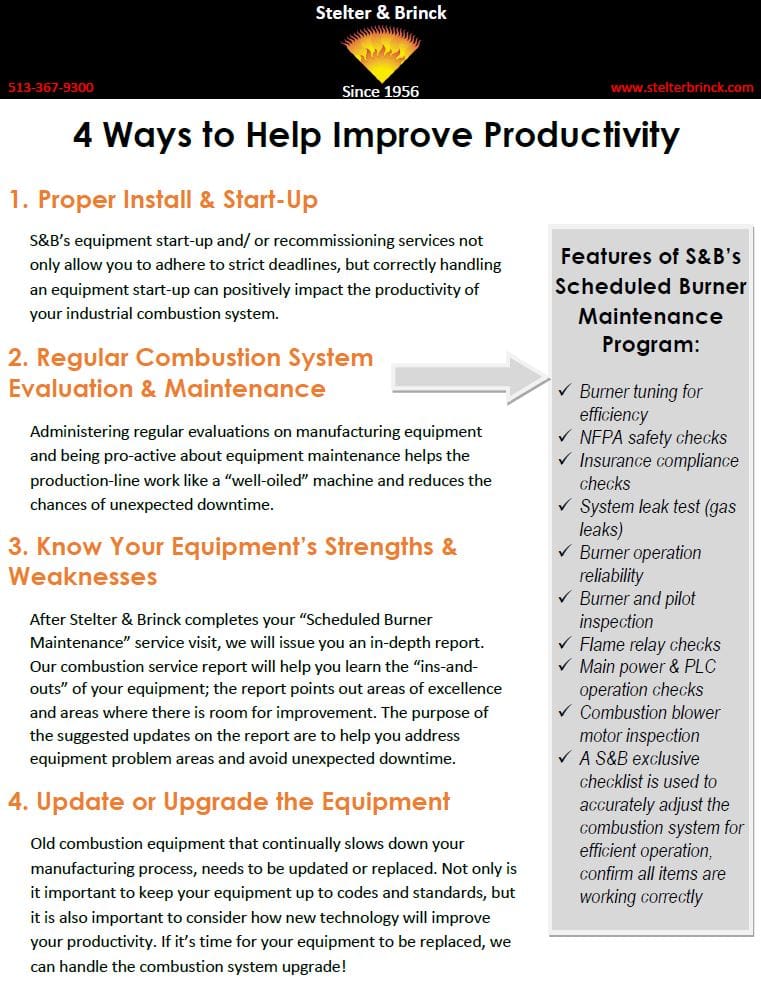

Read More4 Ways to Help Improve Productivity

Below are 4 ways that Stelter & Brinck can help to improve the productivity of your combustion equipment. Proper Install & Start-Up Stelter & Brinck’s equipment start-up & recommissioning services not only allow you to adhere to strict deadlines, but correctly handling an equipment start-up can positively impact the productivity of your industrial combustion system.…

Read More