Posts Tagged ‘Combustion Equipment’

Parts for Combustion Equipment

Do you have spare parts on-hand in the event of an unexpected failure? Does your in-house inventory consist of critical replacement parts? Rely on Stelter & Brinck’s Spare Parts Department for your combustion equipment spares! Benefits of Stelter & Brinck Parts Department: Our Parts Department cannot only help to minimize downtime, but offers: Some of…

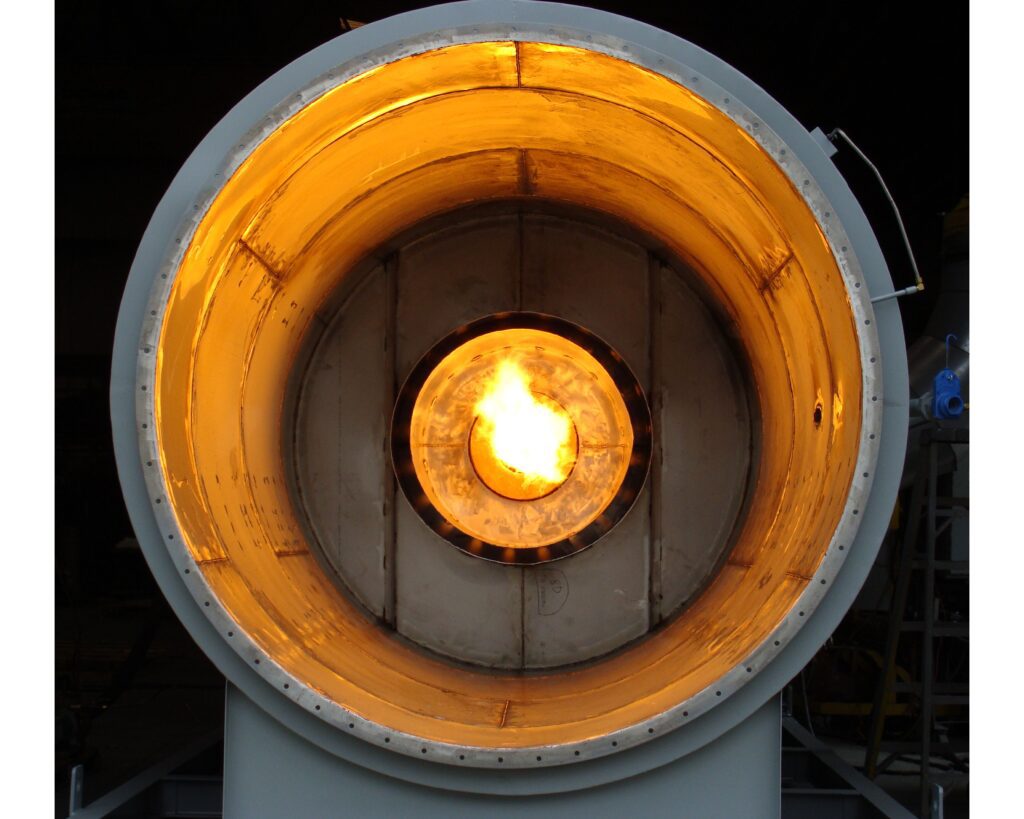

Read More22-Burner Combustion System Test-Fire

To view the video, please click on the image above! All equipment manufactured by Stelter & Brinck is rigorously tested and/or fired at the factoryprior to shipment by our internal Quality Control Team- the customer is always invited!The benefits/ features of our test-fire program include: Equipment is Subjected to a thorough Final Inspection and QCChecklist…

Read More14 Reasons to Include S&B in your Process Heat Budget:

S&B would love to work with your team- if you need a quote or have questions, don’t hesitate to contact us! 513-367-9300 or https://stelterbrinck.com/contact-us/

Read MoreIndustrial Air Heater Vs. HVAC Air Handler

Industrial air heaters and HVAC handling systems can both be direct fired or indirect fired to provide heated air.

Read MoreCustom Combustion Projects

From the food manufacturing to metal processing, we built equipment for various industries last calendar year. While every piece of Stelter & Brinck equipment is custom designed by our engineers and built in our plant, below are a few pictures of some custom combustion projects.

Read MoreCombustion Equipment Test-Fire Video

Stelter & Brinck’s combustion equipment is tested and/or fired in-house prior to shipment. We’re capable of firing propane, natural gas, and fuel oil and we are able to duplicate overseas electric power as well. As mentioned in the video, the benefits of in-house equipment test-firing include, but are not limited to:

Helps eliminate start-up problems and reduce on-site start-up time

Allows you to adhere to tight schedules

Results of all tests are recorded along with factory limit settings, flow rates and control settings

The customer is always invited to witness equipment test firings

Read MoreNew Website

We are so excited to announce the launch of our new website! ✓ Optimized layout ✓Improved user experience ✓Newer (and more) images ✓ Updated product information ✓Related product suggestions Here is a sneak peak of our new website… Click here to check it out!

Read MoreCase Study: Spent Catalyst Recycler

S&B’s solution: Stelter & Brinck provided the customer with on-going preventative maintenance and on-site operator training for the plant’s process heat equipment.

Read MoreExciting News at Stelter & Brinck

In 2022, we will be celebrating 100 Years in the process heating industry! Although we began selling combustion systems in 1956 (as our represented on our logo), we were founded in 1922. We got our start in the process heat industry as a manufacturer’s representative, selling the first industrial burners and controls.

Read MoreImprove Combustion System Reliability & Maximize Operational Efficiency with S&B (Infographic)

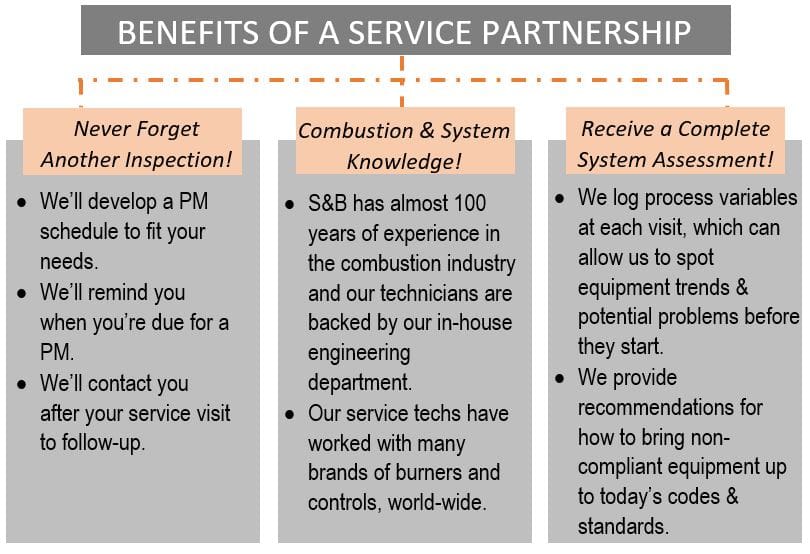

It’s no secret that regular Preventative Maintenance on your Industrial Burner Systems will help keep your equipment running at optimal efficiency and will also improve reliability. By partnering with Stelter & Brinck for your PMs, not only will your system benefit, but you will also benefit in the following ways: You’ll never forget another combustion…

Read More