Posts Tagged ‘combustion field services’

Thermal Oxidizer Case Study

“Our 24/7 manufacturing operation requires robust equipment. S&B has resigned our equipment to meet those standards. We are now able to keep our equipment up and running 24/7. Due to Stelter & Brinck upgrades, our equipment is very reliable.”

Read MoreLooking for Process Heat Equipment or Combustion Service/ Parts?

Does your plant need combustion equipment? Do you need a reputable company for your burners’ maintenance and required safety checks? Are you in need of a combustion equipment parts vendor? If you answered “Yes!†to any of the questions above, partner with Stelter & Brinck for your combustion needs! S&B can provide you with following…

Read MoreCase Study: Spent Catalyst Recycler

S&B’s solution: Stelter & Brinck provided the customer with on-going preventative maintenance and on-site operator training for the plant’s process heat equipment.

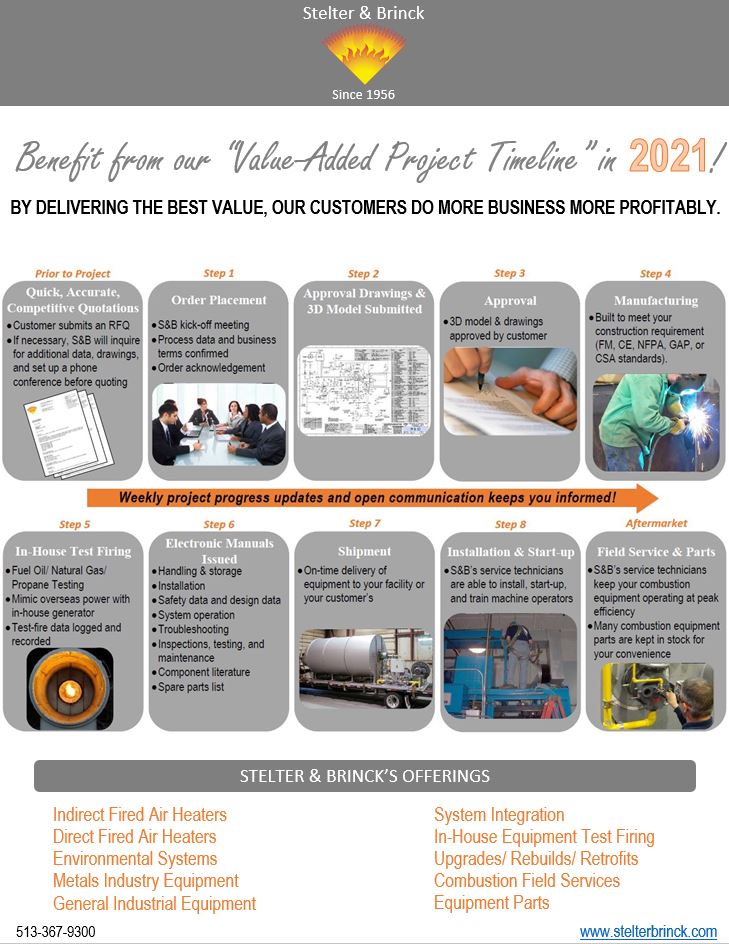

Read MoreInclude Stelter & Brinck in your 2021 budget!

If your plant is in need of new or updated process heat equipment or combustion services, include Stelter & Brinck in your 2021 budget! By delivering the best value, we are able to help our customers do more business more profitably. Stelter & Brinck process heat offerings include: -Indirect Fired Air Heaters -Direct Fired Air…

Read MoreCombustion and Burner Service: Importance & Benefits

Importance of Industrial Burner Preventative Maintenance provided by Stelter & Brinck Virtually every industry from food and chemical production to polymer and steel processing uses burners and therefore, can benefit from industrial burner preventative maintenance. Stelter & Brinck’s exclusive checklist used during regular burner maintenance helps companies improve safety and comply with codes and standards.…

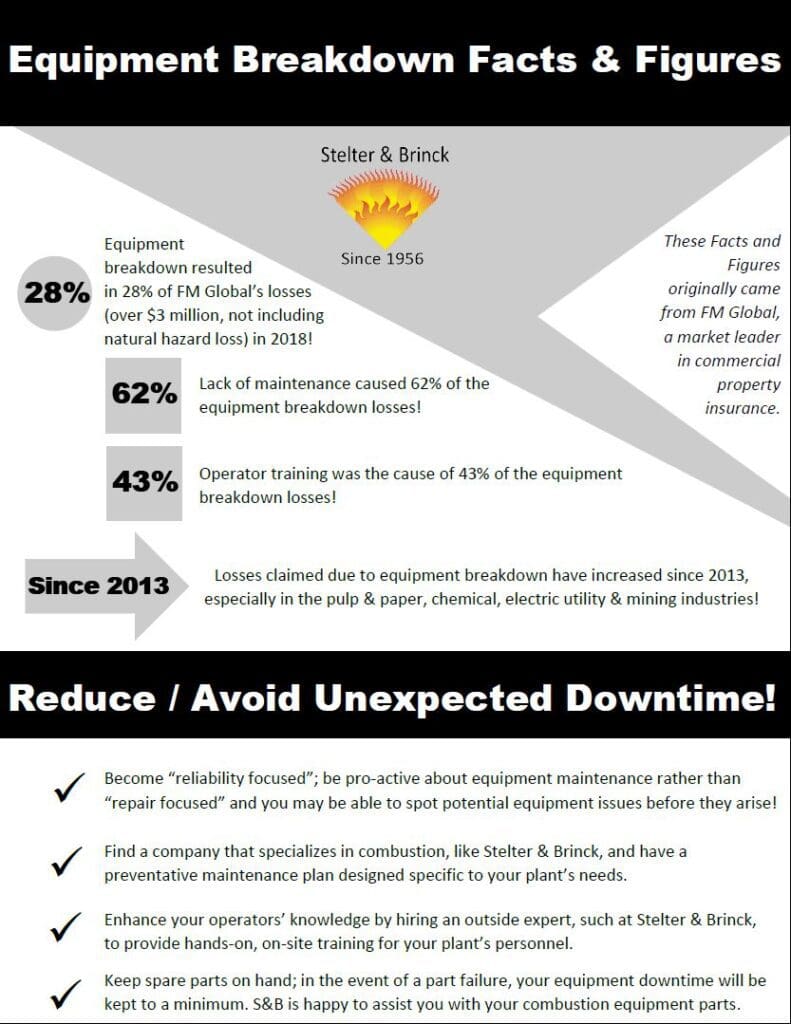

Read MoreEquipment Breakdown Facts and Figures (Infographic)

As you can see from the infographic above, according to FM Global, losses claimed due to equipment breakdown have increased since 2013, especially in the pulp & paper, chemical, electric utility & mining industries! In order to reduce/ avoid unexpected downtime, you can do the following: 1. Become “reliability focusedâ€; be pro-active about equipment maintenance rather…

Read MoreScheduled Burner Preventative Maintenance Case Study: Wood Plastic Composite Manufacturer

Situation: Composite wood is manufactured by combining particles of wood together with plastic. Since its introduction into the outdoor living market in the 1990’s, composite has become a popular alternative to traditional wood decking and railing. Not only is composite easy to install and maintenance-free, but it doesn’t rot, warp, fade, weather or splinter. In…

Read More