Posts Tagged ‘process heat equipment’

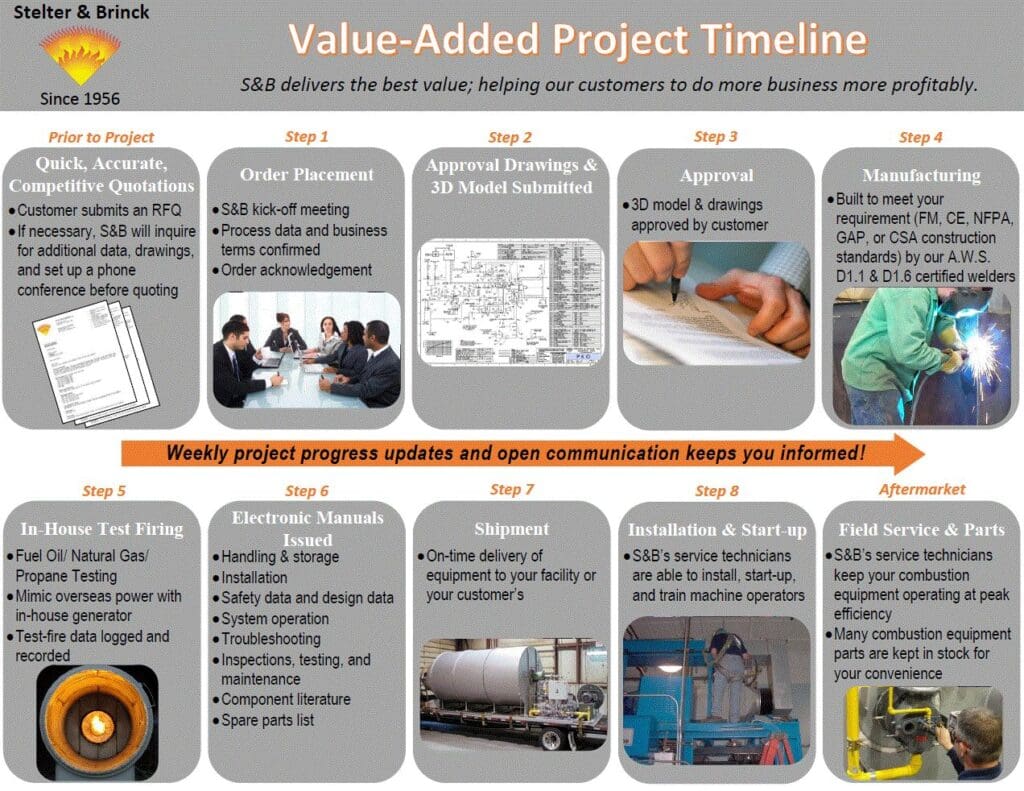

Stelter & Brinck: The Best Value Process Heat Equipment Partner

If you are in the market for process heat equipment, partner with Stelter & Brinck! Our goal is to provide YOU the best value. What does that mean? Stelter & Brinck provides the best value by implementing internal systems and practices on our end, so on your end you may do more business, more profitably for…

Read MoreUpdated Process Equipment Brochure

Stelter & Brinck’s UPDATED capabilities catalog is now available for download!! Click on the image above to view new pictures of our process heat equipment & new product lines! Once you fill out the form, you can download, email or print a copy of our Process Heat Equipment & Combustion Field Services Guide!

Read MoreProcess Heat Equipment & Systems Supplier Selection

Purchasing equipment isn’t a simple decision. There are many factors to take into consideration: What is the OEM’s history in the market and what applications have they worked with? Will their equipment be built correctly? Will their equipment arrive on-time? What are their terms & conditions? Are they a good partner? What value do they…

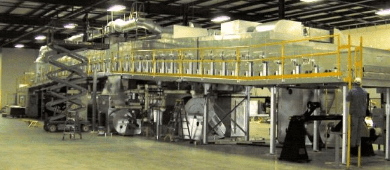

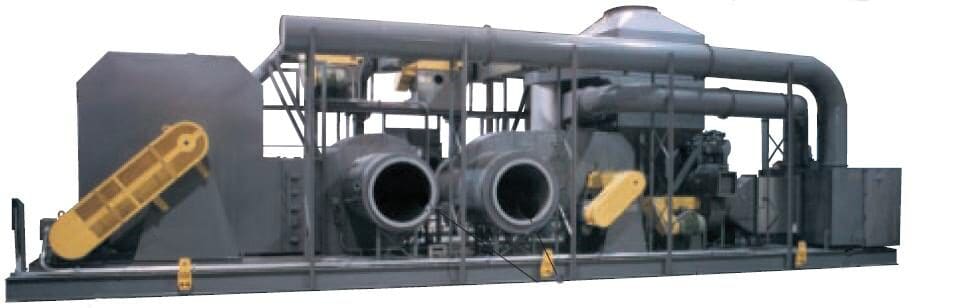

Read More2018 Custom Combustion System Pictures

Below are a few of our custom combustion projects from 2018! We are very thankful for our customers; we had the pleasure of providing custom equipment to numerous industries in various areas of the world. We’re excited for what 2019 may bring! Stelter & Brinck is always happy to discuss any combustion projects. Feel free…

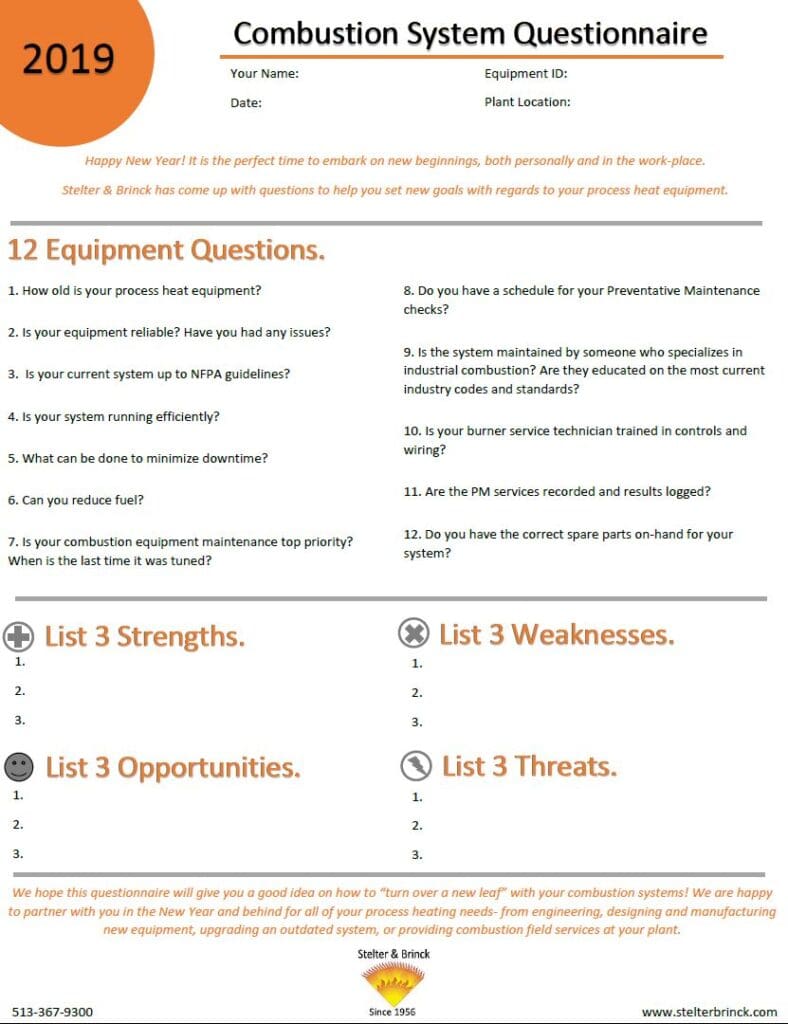

Read MoreCombustion System Questionnaire

Happy New Year! Now is the perfect time to embark on new beginnings, both in your personal life and in the work-place. In order to help you set new goals with regards to your plant’s process heat equipment, we’ve generated a list of questions: How old is your process heat equipment? Is your equipment reliable?…

Read MoreAdhesive Coating Ovens Testimonial

Situation: Adhesives are used in virtually every industry- from pharmaceutical and health to business and technical products. Each application is different and thus, adhesive coating equipment must have versatile and flexible manufacturing capabilities. When the coating line became dated at one of the most well-known adhesive manufacturing facilities, they knew upgrades were necessary in order…

Read MoreOur Process Heat Equipment is Easy to Maintain!

Purchasing process heat equipment? Deciding between custom equipment or a “one-size-fits-all†system? Before you purchase, you’ll want to consider maintenance costs and time. Regular maintenance will help keep your heating equipment running efficiently and minimize unexpected downtime, but how much time will these preventative maintenance visits take from production? Stelter & Brinck’s equipment is custom designed to…

Read More3rd YouTube Video: Benefits of Partnering with Stelter & Brinck

In our last blog post, we featured a YouTube video which highlighted facts about our company that may come as a surprise to some. We have just posted our 3rd YouTube Video and want to share this video with you as well: We created this video to emphasize that we partner with our customers; we work…

Read MoreSystem Integration

When purchasing a new processing system, a company typically gets bids for each individual piece of equipment, which when put together make up the entire system. The system is like a puzzle- in order for the entire process to begin running- each piece of equipment must arrive on-time and be capable of working in conjunction…

Read More