Posts Tagged ‘Combustion Equipment’

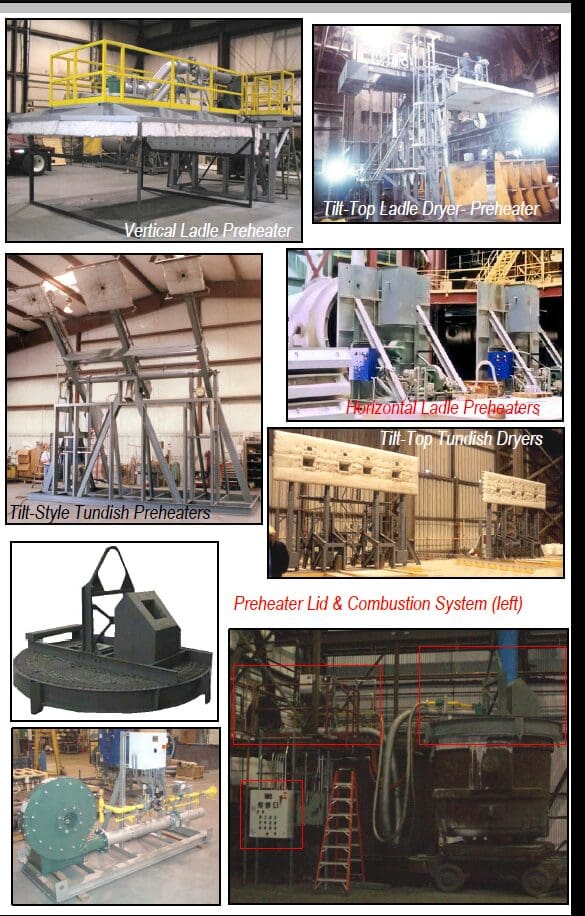

Ladle & Tundish Dryers & Preheaters for the Metals Industry

What are Tundish & Ladles? Dryers, Preheaters, & Dryer-Preheaters? The function of ladles and tundishes in the metal industry and the purpose of dryers/ preheaters is discussed below: Since 3000 B.C. people have been casting and molding metal, originally to make weapons. Today, metal casting and molding is not only used to manufacture weapons, but…

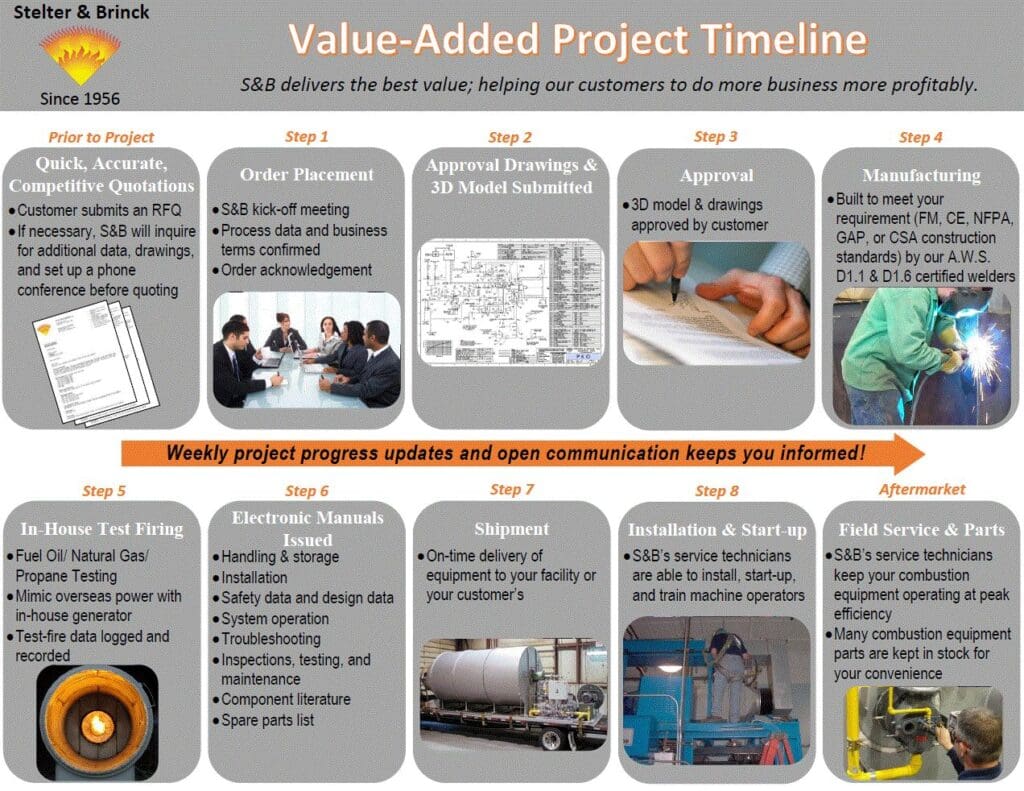

Read MoreStelter & Brinck: The Best Value Process Heat Equipment Partner

If you are in the market for process heat equipment, partner with Stelter & Brinck! Our goal is to provide YOU the best value. What does that mean? Stelter & Brinck provides the best value by implementing internal systems and practices on our end, so on your end you may do more business, more profitably for…

Read MoreProcess Heat Equipment & Systems Supplier Selection

Purchasing equipment isn’t a simple decision. There are many factors to take into consideration: What is the OEM’s history in the market and what applications have they worked with? Will their equipment be built correctly? Will their equipment arrive on-time? What are their terms & conditions? Are they a good partner? What value do they…

Read MoreStelter & Brinck’s Complete Repertoire: Steel Mill Case Study

Situation: A leading mill in the steel industry must rely on only the best resources in order to maintain their highly regarded market position. When the mill’s Facility Combustion Engineer needed help executing his new ideas and helping him solve combustion problems, he knew he’d have to utilize “the best†company. Solution: The Facility Combustion…

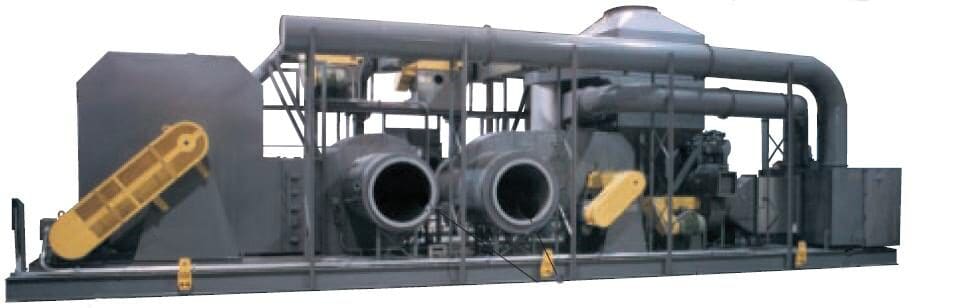

Read More2018 Custom Combustion System Pictures

Below are a few of our custom combustion projects from 2018! We are very thankful for our customers; we had the pleasure of providing custom equipment to numerous industries in various areas of the world. We’re excited for what 2019 may bring! Stelter & Brinck is always happy to discuss any combustion projects. Feel free…

Read MoreCombustion Service Case Study: Spent Catalyst Recycler

Spent Catalyst Recycler Customer Testimonial Situation: Spent catalysts are catalysts that are used and inactive. Strategic metals can be recovered from spent catalysts and then produced into high-purity specialty products. Because the purity of the reclaimed metals is imperative to the quality of the end product, spent catalyst recyclers must work to optimize the value…

Read MoreCombustion Service Partner vs. Vendor

In today’s economy, companies are doing more with less; businesses are finding ways to be more efficient with their resources in order to yield more output per capita. As a result, people in the workplace are delegated more responsibilities, cross-trained in various departments, and are busier than ever before. If scheduling preventative maintenance on the…

Read MoreStelter & Brinck Aftermarket Service Overview

In our last blog post, we provided an overview of our Spare Parts Department. But did you know that Stelter & Brinck’s Aftermarket Services include more than just our “Scheduled Burner Maintenance Program†& equipment parts? Regardless of your location, if your process heat equipment is new or existing, or who the OEM is of your…

Read MoreDo you need to schedule burner services?

Does your plant’s combustion equipment need to be tuned? Are you having issues with your combustion systems? Do you have equipment that may be out of code or that may not be safe? Do you need your equipment started-up by professionals? Stelter & Brinck’s field service department provides combustion services world-wide. We’re happy to assist…

Read MoreSystem Integration

When purchasing a new processing system, a company typically gets bids for each individual piece of equipment, which when put together make up the entire system. The system is like a puzzle- in order for the entire process to begin running- each piece of equipment must arrive on-time and be capable of working in conjunction…

Read More