Posts Tagged ‘combustion systems’

Is your Process Heat Equipment Easy to Maintain?

Regular maintenance will help process heating equipment run efficiently and minimize unexpected downtime. However, you may want to consider the ease (and cost) of maintenance when purchasing a new process heat system.

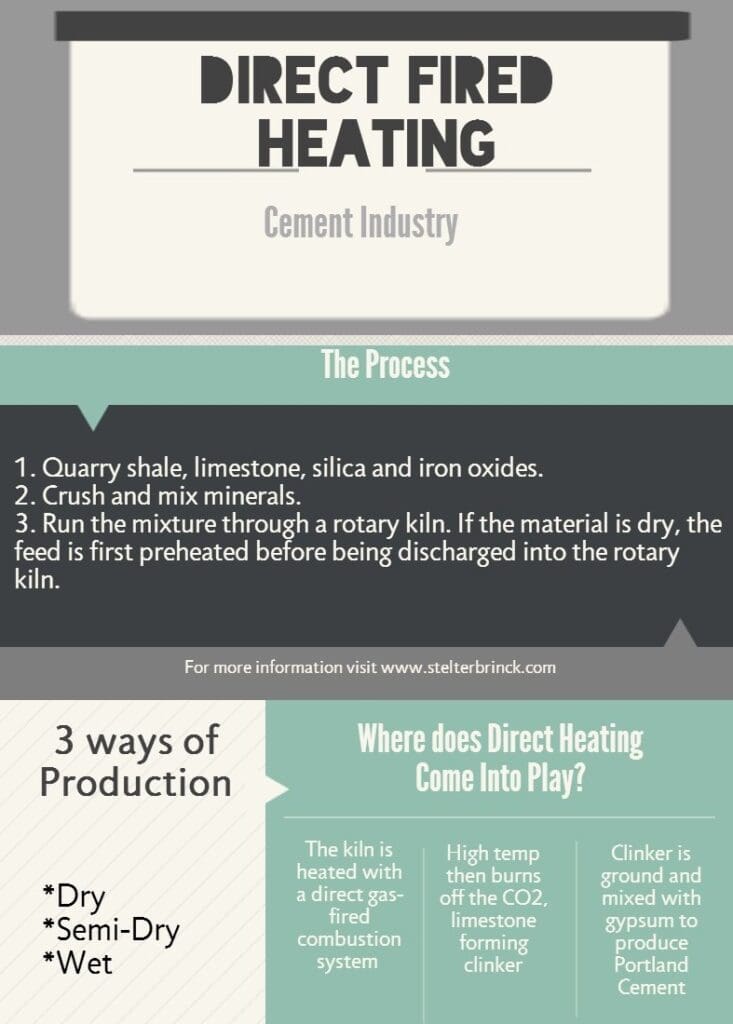

Read MoreDirect Fired Heating in Cement Industry

Originally created in the 1840s, cement has become a keystone product in our society today- it is used to build sidewalks, buildings, streets, parking lots, houses, and much more. Cement production can be done one of three ways: dry, semi-dry or wet processing of various ores to produce a mixture of minerals. The Manufacturing Process…

Read MoreReliable Combustion Equipment?

Is your combustion equipment reliable? Backed by our engineering department, our team of experienced field technicians can bring your equipment up to today’s standards and codes through rebuilds, retrofitting, repairs or upgrades. Examples of equipment upgrades or repairs Stelter & Brinck can help you with: Process Heat Equipment Replacements/ Repairs Oxidizer or Afterburner Replacements/ Repairs Heat…

Read MoreIn-House Equipment Test-Firing

Overview When installing new process heat equipment into your plant, unforeseen hurtles and interruptions can cause tremendous delays, be very costly and cause many headaches. Stelter & Brinck aims to minimize installation set-backs by testing and/or firing your process heat equipment. All process heat equipment manufactured by Stelter & Brinck is rigorously tested and/or fired…

Read MoreSpecialty Ovens and Furnaces

Overview & Features Stelter & Brinck’s specialty ovens and furnaces are custom built units best suited for high temperature applications or for use in harsh environments. The heavy-duty construction of our ovens and furnaces combined with our long history and vast experience in the process heating arena makes for unmatched quality. Among the features are:…

Read MoreImportance of Burner Maintenance in Today’s Workplace

Today, people are “doing less with more†in the workplace. Companies are finding more effective ways to allocate resources. The main reason people are able to yield higher output is due to advancements in technology. Technology has given people the ability to have resources and information at their fingertips, anytime and anyplace. In turn, our…

Read MoreStelter & Brinck Aftermarket Service Overview

In our last blog post, we provided an overview of our Spare Parts Department. But did you know that Stelter & Brinck’s Aftermarket Services include more than just our “Scheduled Burner Maintenance Program†& equipment parts? Regardless of your location, if your process heat equipment is new or existing, or who the OEM is of your…

Read MoreEmissions Goals?

Do you have emissions goals your plant strives to reach? Is your plant looking to become more environmentally friendly? Stelter & Brinck’s equipment can help you meet your emission needs! We manufacture our own line of Environmental Systems, which include: Thermal Oxidizers, Catalytic Oxidizers & Afterburners. These systems destroy industrial emissions that are present in…

Read More