Posts Tagged ‘burner service’

Time to Maintain Those Oven’s Burners!

‘Tis the season for cookies galore! As the days get shorter, and the Holidays near, it seems like cookies are everywhere you turn and it’s easy to overindulge in your favorite treat! According to Wikipedia the modern Christmas cookie recipes can be traced all the back to the 16th century. The ingredients found in cookies…

Read MoreThermal Oxidizer Case Study

“Our 24/7 manufacturing operation requires robust equipment. S&B has resigned our equipment to meet those standards. We are now able to keep our equipment up and running 24/7. Due to Stelter & Brinck upgrades, our equipment is very reliable.”

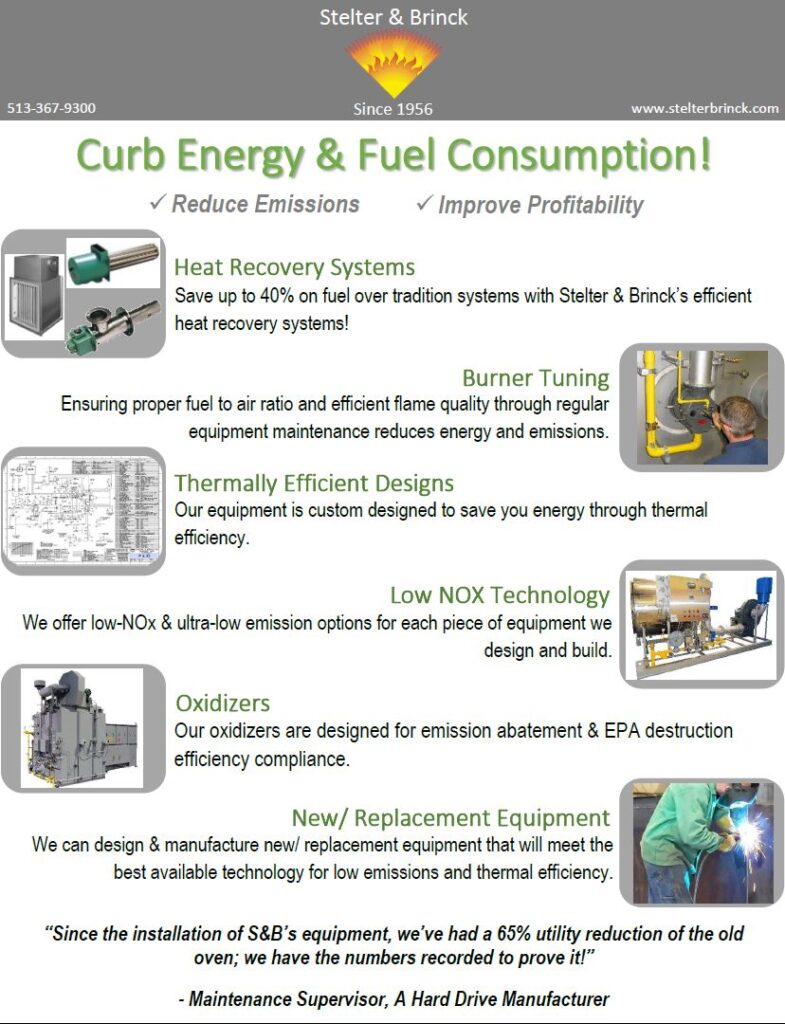

Read MoreCurb Energy & Fuel Consumption

“Since the installation of S&B’s equipment, we’ve had a 65% utility reduction of the old

oven; we have the numbers recorded to prove it!”

– Maintenance Supervisor, A Hard Drive Manufacturer

Mining Company Testimonial

For seven generations, a family-owned New York mining company has produced the world’s highest quality garnet abrasives and powders. Since 1878, these high-performance garnet abrasives have been mined and milled from a unique crystalline hard rock deposit. The company’s products are used in applications such as waterjet cutting, blast media, bonded and coated abrasives, and…

Read MoreIs your Equipment Reliable?

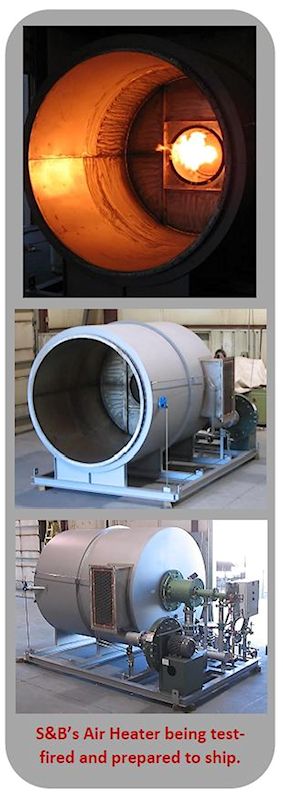

Backed by our in-house engineering team, our experienced service technicians can bring your combustion equipment up to NFPA standards through the following: Preventative Maintenance/ Burner Tune/ Safety Checks Field Rebuilds Retrofitting Repairs Upgrades Customer Success Story: Situation A global leading supplier of fiber-reinforced composites, realized that the air heaters for each of their 5 oven…

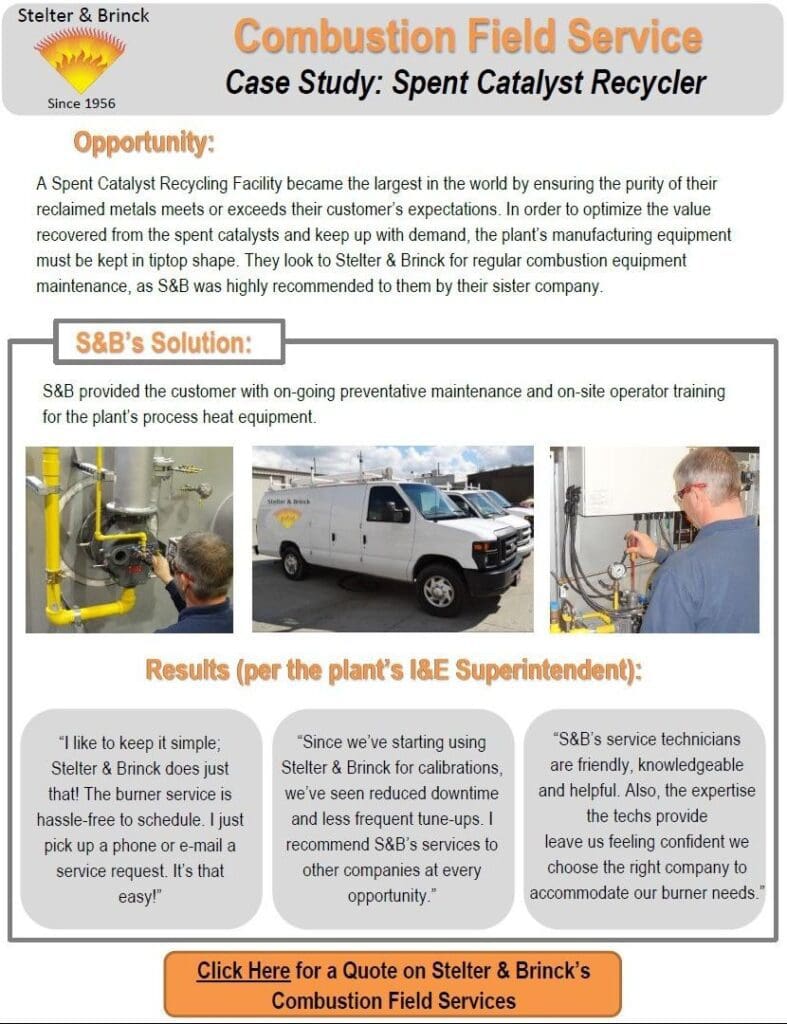

Read MoreCase Study: Spent Catalyst Recycler

S&B’s solution: Stelter & Brinck provided the customer with on-going preventative maintenance and on-site operator training for the plant’s process heat equipment.

Read MoreImprove Combustion System Reliability & Maximize Operational Efficiency with S&B (Infographic)

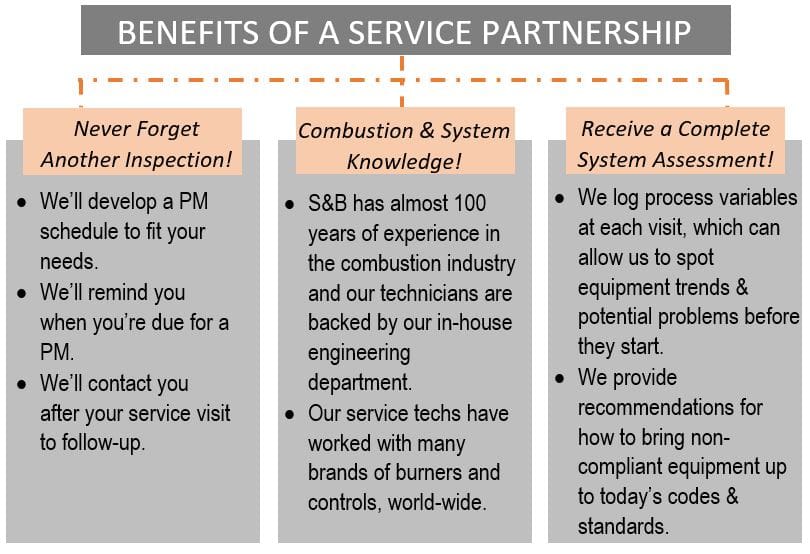

It’s no secret that regular Preventative Maintenance on your Industrial Burner Systems will help keep your equipment running at optimal efficiency and will also improve reliability. By partnering with Stelter & Brinck for your PMs, not only will your system benefit, but you will also benefit in the following ways: You’ll never forget another combustion…

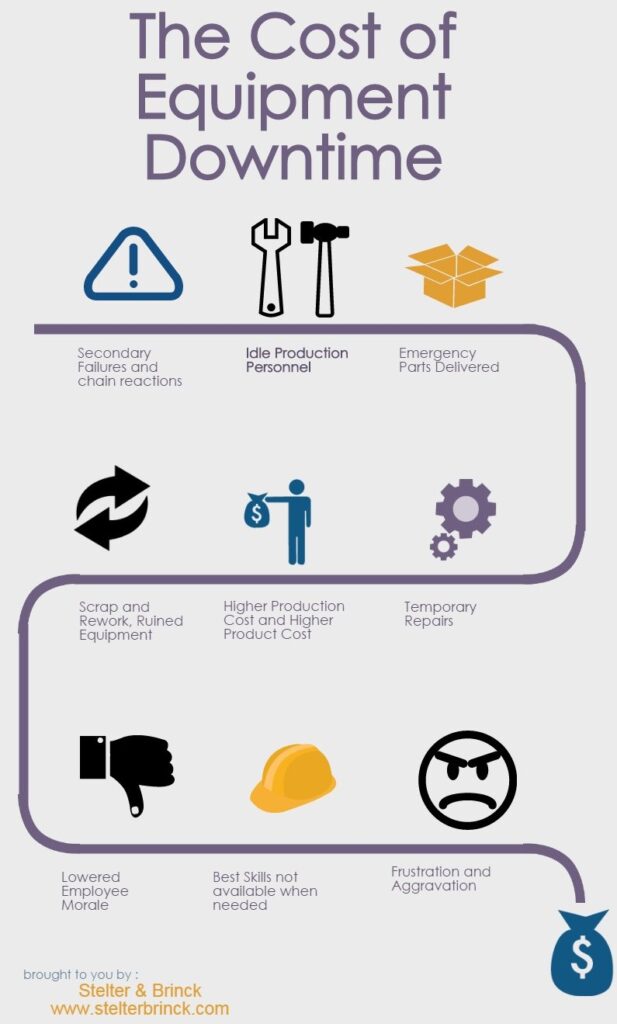

Read MoreThe Real Cost (and 3 Ways to Avoid) Unscheduled Downtime in Manufacturing

Preventative Maintenance (PM) sometimes takes a back seat to other issues on ever-growing “to-do†lists. For many companies, planned maintenance is often an afterthought. If you aren’t experiencing a problem, it is easy to dismiss value of the benefits gained from combustion system preventative maintenance. The True Cost of Equipment Downtime Unpredicted downtown can result…

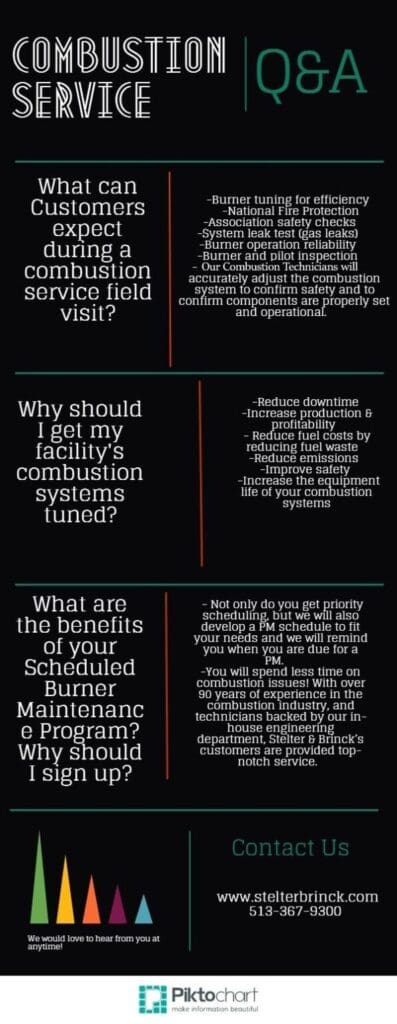

Read MoreCombustion Service Q&A

Q: What can a customer expect during a combustion service field visit? A: All services are performed by a highly skilled, well-trained Stelter & Brinck technician whom is backed by our in-house engineers, and arrives at your facility rested and equipped to take on your combustion needs. Typically, our technicians will perform the following while…

Read MoreStelter & Brinck: History, Products & Partnership

Welcome Hello! It’s been a while since our last post; we’re updating our blog to provide you with higher quality information with regards to: Company information, updates and news (see below) Stelter & Brinck’s product lines (see below) Stelter & Brinck’s product applications Process heating industry tips and tricks Interesting pictures and projects Customer testimonials…

Read More